Jan 23,2026

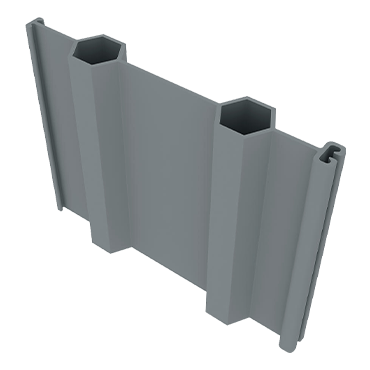

Vinyl sheet piles are long, interlocking sheets made from polyvinyl chloride (PVC), designed to form retaining walls and barriers in water and soil. They are widely used in civil engineering and construction projects to provide soil retention, erosion control, and flood protection. The lightweight nature of vinyl makes them easier to handle and install compared to steel or concrete piles, while offering high corrosion resistance and low maintenance requirements.

Vinyl sheet piles have become a preferred choice in many projects due to their unique combination of properties. Key benefits include:

- Corrosion Resistance: Unlike steel or aluminum, vinyl does not rust or degrade when exposed to water, chemicals, or saltwater environments.

- Lightweight and Easy to Handle: Installation is faster and requires less heavy machinery.

- Durability: Vinyl sheet piles can last for decades without significant maintenance.

- Flexibility in Design: They can be cut and shaped to meet project-specific requirements, including curves and varying wall heights.

- Cost-Effective: Lower installation and maintenance costs compared to steel and concrete options.

What Are the Typical Applications of Vinyl Sheet Piles?

Vinyl sheet piles are used in diverse construction and water management projects. Some common applications include:

- Marine Construction: Docks, piers, seawalls, and bulkheads.

- Flood Control: Levees, retaining walls, and riverbank stabilization.

- Residential Landscaping: Garden retaining walls, ponds, and small waterfront structures.

- Industrial Applications: Soil retention, containment walls, and erosion prevention at construction sites.

- Environmental Projects: Wetland preservation and shoreline stabilization without harmful chemical impact.

How Are Vinyl Sheet Piles Installed?

Installation of vinyl sheet piles requires careful planning to ensure structural integrity. Common installation methods include:

Driving with a Vibratory Hammer

Vibratory hammers are commonly used to drive vinyl sheet piles into soil. This method minimizes noise, vibration, and disturbance of the surrounding area, making it suitable for residential or sensitive environments.

Jetting Method

Water jetting uses high-pressure water streams to assist in driving sheet piles into soft soils. This method is especially effective in sandy or loose soil conditions, reducing installation effort and potential pile damage.

Anchoring and Bracing

In taller walls or areas with high lateral pressure, vinyl sheet piles are often anchored with tiebacks or supported with wales and braces. This ensures long-term stability and prevents deformation under load.

What Are the Advantages and Limitations of Vinyl Sheet Piles?

Advantages

- Lightweight and easy to transport and install.

- Long-lasting resistance to corrosion, UV exposure, and chemicals.

- Environmentally friendly, non-toxic, and low maintenance.

- Cost-effective alternative to steel, concrete, or aluminum piles.

- Versatile design options for curves, wall height, and interlocking patterns.

Limitations

- Limited load-bearing capacity compared to steel, making them less suitable for very high structural loads.

- Performance depends on soil type; very hard or rocky soil can complicate installation.

- Vinyl may soften under extreme heat or become brittle in extreme cold, although UV-stabilized versions mitigate weather effects.

How Do Vinyl Sheet Piles Compare to Steel or Concrete?

Vinyl sheet piles provide a lightweight, corrosion-resistant alternative to traditional steel or concrete piles. While steel offers superior load-bearing capacity and concrete provides mass and rigidity, vinyl excels in marine, residential, and environmentally sensitive projects where durability, maintenance, and installation ease are priorities.

Conclusion: Are Vinyl Sheet Piles the Right Choice?

Vinyl sheet piles offer a practical, cost-effective solution for soil retention, flood protection, and marine construction projects. Their durability, ease of installation, and low maintenance requirements make them ideal for many construction scenarios, though careful consideration of load-bearing and soil conditions is essential for optimal performance.

English

English 中文简体

中文简体