Feb 17,2026

Clarifying the Terminology: Vinyl and PVC Are the Same Material

The question of vinyl sheet piling versus PVC sheet piles represents a common source of confusion in the marine construction and earth retention industry. The straightforward answer is that vinyl and PVC refer to the same base material: polyvinyl chloride. The term "vinyl" serves as the common, shortened name for PVC, much like "plastic" describes a broad category of polymer materials. When manufacturers, engineers, or contractors discuss vinyl sheet piles or PVC sheet piles, they are describing products made from the same fundamental polymer compound, though specific formulations, reinforcement methods, and manufacturing processes may vary between products and manufacturers.

The interchangeable use of "vinyl" and "PVC" in product descriptions stems from marketing preferences, regional terminology differences, and industry conventions rather than actual material distinctions. Some manufacturers prefer "vinyl sheet piling" emphasizing the material's flexibility and consumer familiarity with vinyl products, while others use "PVC sheet piles" highlighting the technical polymer designation that appeals to engineers and specifiers. Understanding this terminology equivalence prevents confusion when comparing products, reviewing specifications, or discussing project requirements. However, while the base material remains consistent, significant differences exist between various PVC sheet pile products based on formulation additives, internal reinforcement structures, manufacturing quality, and design profiles that genuinely impact performance and suitability for specific applications.

PVC Material Composition and Formulation Variations

Base Polymer and Chemical Structure

Polyvinyl chloride is a synthetic thermoplastic polymer created through the polymerization of vinyl chloride monomers. The resulting material in its pure form is rigid, white, and somewhat brittle. PVC's molecular structure consists of repeating units containing carbon, hydrogen, and chlorine atoms arranged in long chains. This basic polymer provides the foundation for all vinyl sheet pile products, but manufacturers never use pure PVC alone. Instead, they formulate proprietary compounds blending PVC resin with carefully selected additives that modify properties to meet specific performance requirements for marine and earth retention applications.

Critical Additives and Performance Modifiers

Manufacturing high-performance PVC sheet piles requires incorporating multiple additive categories that transform base PVC into engineered structural materials. Impact modifiers, typically acrylic or chlorinated polyethylene compounds, enhance toughness and prevent brittle failure under shock loading or cold temperatures. UV stabilizers including hindered amine light stabilizers (HALS) and UV absorbers protect against solar radiation degradation that could otherwise cause surface chalking, color fading, and mechanical property loss over decades of outdoor exposure. Heat stabilizers prevent polymer chain breakdown during manufacturing and service, with calcium-zinc or organotin compounds preferred over traditional lead stabilizers for environmental and health reasons. Processing aids improve melt flow during extrusion, ensuring uniform wall thickness and consistent quality. Pigments provide color while potentially offering additional UV protection, with gray, black, and earth tones most common for sheet pile applications.

Formulation Differences Between Manufacturers

While all PVC sheet piles share the same base polymer, proprietary formulations create meaningful performance variations between products. Premium manufacturers invest in advanced additive packages optimizing the balance between flexibility, impact resistance, UV stability, and long-term durability. These superior formulations may cost more initially but deliver extended service life and better performance in demanding applications. Budget-oriented products might use minimal additive levels or lower-grade modifiers, potentially limiting cold weather flexibility, UV resistance, or impact tolerance. Specifiers should request detailed material certifications and long-term performance data rather than simply selecting products based on generic "PVC" or "vinyl" descriptions. Third-party testing to ASTM standards provides objective comparison of mechanical properties, weathering resistance, and dimensional stability between different manufacturers' formulations.

Product Design Variations in PVC Sheet Pile Systems

| Profile Type | Wall Thickness | Typical Heights | Best Applications |

| Flat Wall Panel | 0.25-0.5 inches | 3-6 feet | Low-height residential |

| Z-Profile Sheet | 0.375-0.625 inches | 6-10 feet | Standard bulkheads |

| Box Profile | 0.5-0.75 inches | 8-12 feet | Heavy-duty marine |

| Cellular Construction | 0.375-0.5 inches | 6-10 feet | Maximum strength projects |

Internal Reinforcement Technologies

Modern PVC sheet piles incorporate various internal reinforcement strategies that significantly affect structural performance beyond basic material properties. Hollow chamber designs create box sections with multiple internal webs distributing loads and increasing section modulus without excessive material use. Some manufacturers insert fiberglass reinforcement rods or mesh within the PVC profile during extrusion, creating composite structures combining PVC's corrosion resistance with enhanced stiffness from the glass fibers. Foam-filled chambers provide additional strength and impact resistance while maintaining relatively light weight. The sophistication of internal reinforcement design often distinguishes premium products from basic offerings, with advanced geometries maximizing strength-to-weight ratios and providing optimal load distribution for specific wall heights and soil conditions.

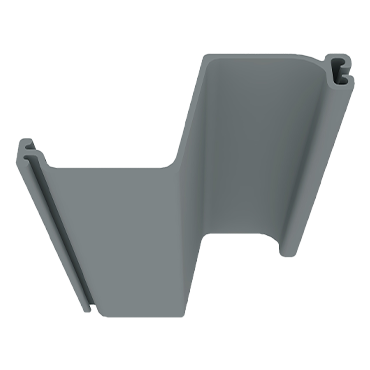

Interlock Joint Systems

The interlocking joints connecting adjacent PVC sheet pile panels critically influence wall performance, installation ease, and long-term durability. Simple tongue-and-groove joints offer basic connection for light-duty applications but may allow soil migration or water seepage under pressure. Advanced joint designs incorporate multiple engagement surfaces, positive locking features, and extended overlap zones that create water-resistant barriers while maintaining connection integrity during driving and under service loads. Some systems include elastomeric gaskets or sealants within joint profiles, creating truly watertight connections for below-grade waterproofing applications. Joint geometry affects installation tolerance, with some designs accommodating minor vertical misalignment between panels while others require precise alignment for proper engagement. Evaluating joint design quality and testing joint performance under realistic loading conditions separates superior products from marginal alternatives.

Manufacturing Process and Quality Considerations

Extrusion Technology

PVC sheet pile manufacturing primarily uses continuous extrusion processes where heated polymer compound flows through precisely machined dies forming the desired profile shape. Modern extrusion lines control temperature, pressure, and flow rate with extreme precision, ensuring consistent wall thickness, accurate dimensions, and uniform material properties throughout each panel length. Co-extrusion technology allows manufacturers to create multi-layer structures with different formulations in outer surfaces versus core material, optimizing surface properties like UV resistance and color while using cost-effective formulations in structural cores. Cooling and sizing operations following the extrusion die stabilize panel dimensions and prevent warping or distortion. Advanced manufacturers employ in-line quality monitoring using laser measurement systems and automated inspection detecting dimensional variations or surface defects in real-time during production.

Quality Control Standards

Reputable PVC sheet pile manufacturers implement comprehensive quality management systems ensuring product consistency and performance reliability. Raw material testing verifies incoming PVC resin and additives meet specifications before compounding. Process control monitors extrusion parameters maintaining optimal conditions throughout production runs. Finished product testing measures critical properties including tensile strength, flexural modulus, impact resistance, and dimensional accuracy against established standards. Long-term performance validation includes accelerated weathering tests simulating years of outdoor exposure, and structural testing verifying load capacity under realistic installation and service conditions. ISO 9001 certification or equivalent quality management system accreditation provides assurance of systematic quality control, while ASTM compliance demonstrates adherence to recognized material and performance standards.

Common Misunderstandings and Marketing Claims

Virgin vs Recycled PVC Content

One legitimate variation between PVC sheet pile products involves the use of virgin versus recycled PVC content. Virgin PVC, manufactured directly from petrochemical feedstocks, offers consistent properties and maximum performance. Some manufacturers incorporate recycled PVC from post-industrial or post-consumer sources, potentially reducing costs and environmental impact. However, recycled content can introduce variability in properties, contamination risks, and reduced long-term durability depending on the source material quality and reprocessing methods. Premium structural applications should specify 100% virgin PVC with certified additives ensuring predictable performance over decades. Products containing recycled content may be suitable for less demanding applications but should be clearly labeled with recycled percentage and supported by testing demonstrating adequate performance for intended use.

Marine-Grade and Premium Designations

Marketing terminology like "marine-grade PVC" or "premium vinyl sheet piling" creates confusion without standardized definitions. These terms should indicate enhanced formulations with superior UV stabilizers, higher impact modifier content, and additional quality testing validating saltwater resistance and long-term durability. However, without specific technical data supporting such claims, these designations may represent marketing differentiation rather than genuine performance advantages. Specifiers should demand detailed formulation information, third-party test results, and warranty coverage backing premium claims. Comparing actual mechanical properties, accelerated aging performance, and manufacturer track records provides more reliable product differentiation than marketing labels alone.

Application-Specific Selection Criteria

Selecting appropriate PVC sheet pile products requires matching material properties and design features to specific project requirements and environmental conditions.

- Saltwater marine applications demand maximum UV stabilization and impact modifiers maintaining flexibility during storms and boat impacts. Premium formulations with proven saltwater exposure history prevent premature degradation in aggressive coastal environments.

- Freshwater lake and pond installations tolerate slightly lower additive packages but still require adequate UV protection and freeze-thaw resistance. Products designed for these applications balance performance with cost efficiency for residential waterfront projects.

- Cold climate installations need enhanced impact modifiers preventing brittle failure at sub-zero temperatures. Testing data demonstrating impact strength at -20°F or lower proves cold weather suitability for northern regions.

- High-UV exposure areas including southern coastal regions and high-altitude locations require maximum UV stabilizer concentrations. Products with documented performance in Florida or Caribbean installations demonstrate adequate sun resistance.

- Chemical exposure scenarios including industrial waterfront or wastewater applications need formulations tested against specific chemicals anticipated in service. PVC generally resists acids, alkalis, and petroleum products but some aggressive chemicals may require special considerations.

Installation Considerations for Different PVC Products

Driving Characteristics and Soil Compatibility

PVC sheet pile products exhibit varying installation characteristics based on profile design, wall thickness, and material stiffness. Thinner-walled panels drive more easily in soft soils but may buckle or deform in dense materials requiring pre-excavation or jetting. Heavier profiles with reinforced sections tolerate driving forces in firmer soils without damage but demand more powerful installation equipment. Joint design affects driving resistance and damage susceptibility, with robust interlocks maintaining engagement during installation while weaker joints may separate requiring careful handling. Manufacturers should provide installation guidelines specifying suitable soil types, recommended driving methods, and maximum driving forces preventing panel damage. Field testing on representative soil conditions before full-scale installation identifies potential issues and validates installation procedures.

Temperature Effects on Installation

PVC's thermoplastic nature creates temperature-dependent installation considerations. Cold temperatures increase material stiffness and reduce impact tolerance, potentially causing cracking if panels are driven forcefully in frozen conditions. Installation in temperatures below 40°F requires extra care, gentle driving techniques, and possibly warming panels before installation. Hot weather softens PVC temporarily, making panels more flexible but potentially affecting dimensional stability during handling and alignment. Extreme heat above 100°F may require installation during cooler morning hours preventing excessive softening. Thermal expansion and contraction between installation and service conditions necessitate appropriate joint gaps and connection details accommodating dimensional changes without creating stress concentrations or joint separation.

Long-Term Performance and Warranty Considerations

Service Life Expectations

Quality PVC sheet piles formulated with appropriate additives and manufactured to high standards deliver service lives exceeding 50-75 years in typical waterfront applications, with some premium products warranted for 100+ years. This exceptional longevity stems from PVC's inherent corrosion resistance and modern UV stabilizer technology preventing polymer degradation. However, inferior products with minimal additives or recycled content may exhibit significantly shorter service lives with surface degradation, embrittlement, or mechanical property loss appearing within 10-20 years. Long-term performance depends critically on initial product quality, proper installation preventing damage, and environmental exposure severity. Manufacturers standing behind their products with substantial warranties backed by performance bonds demonstrate confidence in their formulations and manufacturing quality.

Warranty Coverage and Limitations

PVC sheet pile warranties typically cover material defects and premature degradation but include specific limitations and conditions. Standard warranties might guarantee against UV degradation, cracking, or structural failure for 25-50 years depending on product grade and manufacturer confidence. Premium products may offer extended warranties up to lifetime coverage for residential installations. However, warranties generally exclude damage from improper installation, excessive loading beyond design limits, impact from vessels or debris, and exposure to incompatible chemicals. Some manufacturers void warranties if panels are installed by uncertified contractors or in soil conditions outside recommended parameters. Reading warranty terms carefully and understanding coverage limitations, claim procedures, and manufacturer financial stability ensures warranty value extends beyond marketing promises to genuine protection against product failures.

Understanding that vinyl and PVC sheet piles represent the same base material eliminates terminology confusion, but recognizing significant variations in formulations, manufacturing quality, and design features remains essential for successful project outcomes. The "PVC" or "vinyl" designation alone provides insufficient information for specification decisions. Instead, focus evaluation on specific mechanical properties, UV resistance testing, manufacturer reputation, warranty coverage, and project-appropriate design features. This informed approach to PVC sheet pile selection ensures optimal material performance, long-term durability, and cost-effective solutions for waterfront and earth retention applications across diverse environmental conditions and loading requirements.

English

English 中文简体

中文简体