Jan 28,2026

Introduction to Vinyl Sheet Piles

Vinyl sheet piles, made from high-density PVC or other durable polymers, are increasingly used in civil engineering, marine construction, and flood protection. They serve as retaining walls, bulkheads, cofferdams, and other structural barriers. Vinyl sheet piles are valued for their lightweight nature, corrosion resistance, and ease of installation compared to traditional steel or timber options.

Their versatility makes them ideal for both temporary and permanent structures, particularly in environments exposed to water, chemicals, or harsh weather. Understanding the characteristics, types, and installation methods is crucial for selecting the right vinyl sheet piles for a project.

Materials and Composition

Vinyl sheet piles are typically made from rigid PVC or high-density polyethylene (HDPE). These materials are reinforced with additives to improve impact resistance, UV stability, and durability. Key material properties include:

- High resistance to corrosion and rot, ideal for marine and chemical environments

- Lightweight construction, enabling easier handling and faster installation

- UV-stabilized compounds to prevent degradation in sunlight-exposed areas

- Low maintenance requirements compared to steel or timber piles

Types of Vinyl Sheet Piles

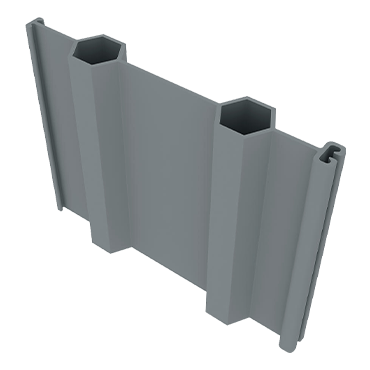

Vinyl sheet piles come in various profiles and dimensions to meet different engineering needs. The main types include interlocking flat panels, U-shaped sections, and Z-shaped profiles:

Interlocking Flat Panels

These panels feature tongue-and-groove connections that allow for quick alignment and installation. They provide a smooth surface finish and are commonly used in residential and commercial waterfront projects where aesthetic appearance is important.

U-Shaped Profiles

U-shaped vinyl piles offer structural rigidity and are ideal for retaining walls and cofferdams. Their design allows for higher load-bearing capacity and better interlocking with adjacent sheets, reducing the risk of movement under lateral soil pressure.

Z-Shaped Profiles

Z-shaped vinyl sheet piles are designed for heavy-duty applications requiring maximum strength and flexibility. They provide excellent interlock resistance, making them suitable for flood protection, seawalls, and harbor infrastructure.

Installation Methods

Proper installation is critical to maximize the performance of vinyl sheet piles. Common methods include driving with vibratory hammers, hydraulic presses, or impact hammers, depending on soil conditions and project requirements.

- Vibratory Hammers: Efficient for soft to medium soils, reducing installation time and vibration impact

- Hydraulic Press: Precise installation with minimal disturbance, suitable for sensitive environments

- Impact Hammers: Ideal for dense or compacted soils, providing deeper penetration

Applications of Vinyl Sheet Piles

Vinyl sheet piles have a wide range of applications in construction and civil engineering. Their resistance to corrosion, rot, and UV exposure makes them ideal for challenging environments.

Flood Protection and Retaining Walls

Vinyl sheet piles are commonly used to construct levees, flood barriers, and retaining walls. Their interlocking profiles prevent water seepage, ensuring structural stability during high-water events.

Marine and Waterfront Projects

Seawalls, docks, bulkheads, and marina construction benefit from vinyl sheet piles due to their corrosion resistance in saltwater environments. They offer a long-lasting solution with low maintenance requirements.

Residential and Landscaping Applications

Vinyl sheet piles are used for decorative retaining walls, garden borders, and small-scale water containment structures. Their aesthetic finishes and lightweight properties make them easy to install for homeowners and landscapers.

Durability and Maintenance

Vinyl sheet piles offer excellent durability, often exceeding 50 years under normal conditions. Key factors contributing to longevity include:

- Resistance to corrosion from saltwater, chemicals, and soil contaminants

- UV stabilization to prevent fading and brittleness

- Minimal maintenance compared to steel or timber alternatives

- Flexibility in expansion and contraction under temperature variations

Comparison with Steel and Timber Sheet Piles

Vinyl sheet piles offer several advantages over traditional steel and timber piles, especially in coastal and chemically aggressive environments. The table below summarizes the key differences:

| Property | Vinyl Sheet Piles | Steel Sheet Piles | Timber Sheet Piles |

| Corrosion Resistance | Excellent, no rust | Moderate to poor, requires coating | Good in freshwater, poor in saltwater |

| Weight | Lightweight, easy handling | Heavy, requires cranes | Moderate, may need machinery |

| Maintenance | Minimal | Regular painting and inspection | Periodic replacement |

| Lifespan | 50+ years | 20-40 years | 15-30 years |

Conclusion

Vinyl sheet piles provide a versatile, durable, and cost-effective solution for retaining walls, marine construction, flood protection, and landscaping projects. Their resistance to corrosion, lightweight handling, and minimal maintenance make them a superior choice in environments where steel or timber may fail.

By understanding the material properties, installation methods, and suitable applications, engineers and project managers can optimize vinyl sheet pile solutions for long-lasting performance and aesthetic appeal.

English

English 中文简体

中文简体