Dec 12,2025

In today’s construction and civil engineering industries, sustainability, durability, and cost efficiency are top priorities. Among the wide range of materials used for earth retention, seawalls, and flood protection, one product has gained increasing attention: the vinyl sheet pile.

Also known as PVC sheet piles, these modern structures are redefining how engineers approach waterfront development, soil stabilization, and erosion control. But what makes vinyl sheet piles so special? How do they compare to traditional steel, concrete, or wood alternatives? And why are they considered one of the most sustainable solutions for the future?

This comprehensive article explores the definition, composition, manufacturing process, advantages, applications, and environmental benefits of vinyl sheet piles — and explains why they have become a go-to choice in marine and civil infrastructure.

1. What Are Vinyl Sheet Piles?

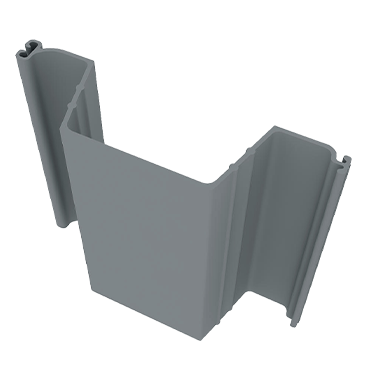

Vinyl sheet piles are interlocking wall panels made from polyvinyl chloride (PVC), designed to form continuous barriers for soil or water retention. Each panel has a tongue-and-groove or lock-joint edge that allows the sheets to connect seamlessly, creating a watertight wall.

These sheet piles are lightweight yet extremely durable, offering resistance against corrosion, rot, and chemical exposure. They are commonly used in:

- Seawalls and bulkheads

- Riverbanks and canal walls

- Flood protection barriers

- Retaining walls for landscaping

- Groundwater cut-off walls

Unlike steel or timber, vinyl does not rust, warp, or decay, making it a long-lasting and low-maintenance alternative.

2. How Are Vinyl Sheet Piles Made?

The manufacturing process of vinyl sheet piles involves extrusion molding, a method where PVC resin and stabilizing additives are melted and forced through a die to produce continuous profiles.

Step 1: Raw Material Preparation

High-quality PVC resin is blended with UV stabilizers, plasticizers, and impact modifiers to enhance flexibility, weather resistance, and durability.

Step 2: Extrusion

The molten mixture is extruded through a die that shapes it into the desired sheet pile profile — typically with interlocking edges.

Step 3: Cooling and Cutting

The extruded sheet is rapidly cooled and cut to length, ensuring straightness and dimensional accuracy.

Step 4: Quality Inspection

Each pile is checked for thickness, tensile strength, and interlock performance to ensure consistent structural quality.

This precise process results in high-performance sheet piles that can last over 50 years, even in harsh marine environments.

3. What Are the Main Properties of Vinyl Sheet Piles?

Vinyl sheet piles possess several mechanical and environmental advantages that make them ideal for challenging construction conditions.

| Property | Description |

| Corrosion Resistance | Immune to rust, rot, and marine borers. |

| UV and Weather Resistant | Can withstand long-term sun exposure and extreme temperatures. |

| Chemical Resistance | Resistant to saltwater, acids, and alkalis. |

| Lightweight | Easy to transport, handle, and install. |

| Watertight Interlocks | Prevent seepage and soil erosion. |

| Aesthetic Appearance | Available in various colors and finishes for architectural harmony. |

| Recyclable Material | 100% recyclable and environmentally friendly. |

These features make vinyl sheet piles an excellent choice for both functional and aesthetic engineering solutions.

4. Why Are Vinyl Sheet Piles Considered ECO-Friendly?

In the construction sector, sustainability is no longer optional — it’s a necessity. Vinyl sheet piles contribute to eco-friendly construction in several ways:

-

Non-Toxic Composition:

PVC used in sheet piles is free from hazardous chemicals and heavy metals, making it safe for marine and soil environments. -

Recyclable Material:

Vinyl can be reprocessed and reused, reducing waste generation. -

Low Carbon Footprint:

The production of vinyl piles consumes less energy compared to steel or concrete manufacturing. -

Long Service Life:

Their durability reduces the need for replacements, minimizing material waste over decades. -

No Leaching or Pollutants:

Vinyl does not corrode or release harmful substances into water or soil.

Thus, vinyl sheet piles perfectly align with green building practices and sustainable engineering standards worldwide.

5. How Do Vinyl Sheet Piles Compare with Traditional Materials?

To understand their growing popularity, it’s important to compare vinyl with conventional sheet pile materials like steel, wood, and concrete.

| Feature | Steel Sheet Piles | Wood Sheet Piles | Concrete Sheet Piles | Vinyl Sheet Piles |

| Corrosion Resistance | Poor in saltwater | Prone to decay | Moderate | Excellent |

| Weight | Heavy | Moderate | Very heavy | Lightweight |

| Installation | Requires heavy equipment | Easy | Difficult | Easy |

| Durability | High (with coating) | Low | High | High |

| Maintenance | Regular anti-rust treatment | Frequent replacement | Cracking risk | Minimal |

| Environmental Impact | High energy and carbon | Deforestation | Cement emissions | Low carbon and recyclable |

This comparison highlights vinyl’s unique balance of performance, durability, and eco-responsibility, making it one of the most cost-effective modern alternatives.

6. Applications of Vinyl Sheet Piles

Vinyl sheet piles are highly versatile and are used across diverse industries and project types.

a. Marine and Coastal Engineering

Used for seawalls, jetties, and harbor protection, vinyl sheet piles offer superior resistance to saltwater corrosion, ensuring long-term shoreline stability.

b. River and Canal Banks

They help control erosion, stabilize slopes, and maintain water flow integrity in rivers and canals.

c. Flood Protection Systems

Vinyl sheet piles serve as permanent floodwalls or levee reinforcements, preventing water intrusion during storms or rising tides.

d. Retaining Walls and Earthworks

They are ideal for soil retention in landscaping, basements, or underground structures, offering both function and visual appeal.

e. Environmental Containment

Used in groundwater cut-off walls and landfill barriers to prevent contamination spread from industrial or waste sites.

f. Residential and Aesthetic Projects

Architects use vinyl piles for decorative fences, ponds, and lakeshores where durability and clean appearance are important.

7. How Are Vinyl Sheet Piles Installed?

Vinyl sheet pile installation is relatively simple and efficient compared to traditional materials.

Typical steps include:

- Site Preparation: Marking alignment and driving points.

- Driving the Sheets: Using vibratory hammers, drop hammers, or water jetting to embed sheets into the soil.

- Interlocking and Alignment: Each pile interlocks tightly with the next to ensure a continuous wall.

- Capping and Finishing: The top is capped with a structural beam or concrete for added strength and appearance.

Because vinyl is lightweight, installation requires less equipment, less time, and lower labor costs, making it highly economical.

8. What Are the Key Advantages of Vinyl Sheet Piles?

1. Exceptional Longevity:

Can last 50–75 years with minimal maintenance.

2. Cost-Effective:

Reduced transport, installation, and maintenance costs make it cheaper over its lifetime.

3. Corrosion and Rot Resistance:

Perfect for saltwater and humid environments.

4. Lightweight and Easy to Handle:

Ideal for remote or limited-access construction sites.

5. Attractive Appearance:

Smooth, uniform finish enhances aesthetics for visible waterfront projects.

6. Environmentally Responsible:

Recyclable, non-toxic, and energy-efficient to produce.

7. Flexible Design Options:

Available in various colors, shapes, and thicknesses to suit project requirements.

9. What Challenges Do Vinyl Sheet Piles Face?

Despite their advantages, vinyl sheet piles have certain limitations:

- Lower structural strength than steel for very deep or heavy-load applications.

- Temperature sensitivity — extreme cold can cause brittleness.

- Limited load-bearing capacity for high-pressure industrial foundations.

However, manufacturers are addressing these challenges by developing reinforced composite sheet piles, combining fiberglass or steel cores with vinyl exteriors for added strength and flexibility.

10. Future Trends and Innovations

The vinyl sheet pile industry is evolving rapidly with advancements in polymer science and extrusion technology.

Emerging trends include:

- Reinforced PVC composites for enhanced strength.

- Recycled-content sheet piles to promote circular economy practices.

- Improved UV and thermal stabilizers for longer lifespan.

- Hybrid systems combining vinyl with steel for heavy-duty applications.

- Smart installation monitoring using sensors for real-time wall stability tracking.

These innovations are making vinyl sheet piles increasingly viable for large-scale marine infrastructure and climate adaptation projects.

11. Environmental and Economic Impact

The adoption of vinyl sheet piles provides measurable environmental and financial benefits:

Environmental Benefits:

- Reduced steel consumption and mining impact.

- Lower CO₂ emissions during production.

- Longer service life minimizes material waste.

- 100% recyclability reduces landfill disposal.

Economic Benefits:

- Faster installation lowers project timelines.

- Minimal maintenance cuts operational costs.

- Extended lifespan ensures long-term value.

Thus, vinyl sheet piles offer a win-win solution — cost efficiency for engineers and sustainability for the planet.

12. Conclusion: Are Vinyl Sheet Piles the Future of Civil Engineering?

So, why are vinyl sheet piles becoming the preferred choice for engineers and developers worldwide?

Because they represent the perfect balance of performance, durability, and environmental responsibility. With their lightweight design, corrosion resistance, and sustainable production process, vinyl sheet piles are revolutionizing waterfront, flood control, and soil retention projects.

As the construction industry moves toward greener, longer-lasting materials, vinyl sheet piles stand at the forefront of sustainable engineering — protecting coastlines, conserving resources, and shaping the future of resilient infrastructure.

English

English 中文简体

中文简体