Feb 28,2026

Introduction: why proactive maintenance matters for vinyl sheet piles

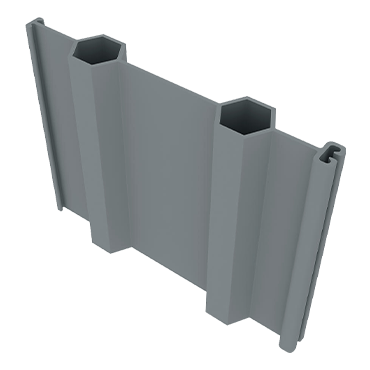

Vinyl (PVC-u) sheet piles are increasingly used for waterfront structures, erosion control, and small quay walls because they resist corrosion, are lightweight, and are easy to install. However, like any engineered material exposed to water, sunlight, and mechanical loads, vinyl sheet piles require a targeted maintenance program to remain effective and safe for decades. Proactive maintenance maximizes structural life, reduces total cost of ownership, prevents unexpected failures, and ensures environmental compliance in sensitive marine and riparian settings.

Routine inspection program: what to check and how often

A routine inspection program is the backbone of vinyl pile maintenance. Frequency should be risk-based: high-energy marine sites or locations with heavy boat traffic need inspections every 3–6 months, while sheltered sites may require annual checks. Inspections should be more frequent after major storms, vessel impacts, or ice events. Use the same checklist each time to spot trends and degrading conditions.

Visual inspection items

Visually inspect for surface cracking, UV-induced chalking, discoloration, bulging or delamination at coated surfaces, visible seam separation on interlocks, and any evidence of mechanical impact (dents, gouges). Also check for biological growth such as barnacles or heavy algal mats that can hide damage and increase hydrodynamic loads.

Functional inspection items

Assess interlock functionality by checking for excessive gaps when driven piles are exposed (e.g., during low tide). Verify anchor or tie-rod tension where applicable. Look for localized settlement or rotation of supported soil and monitoring instrumentation such as inclinometers or piezometers, if installed.

Cleaning and biofouling control

Biofouling (barnacles, mussels, algae) and surface deposits reduce appearance, add weight, and may trap moisture against the pile, accelerating photodegradation in crevices. Regular cleaning keeps surfaces visible for inspection and reduces hydrodynamic drag.

Recommended cleaning methods

For light fouling, pressure washing with freshwater at moderate pressure (1000–2000 psi) removes slime and soft growth. For heavy barnacle or mussel growth, use scraping tools designed for plastics (plastic or nylon scrapers) to avoid gouging the vinyl. Avoid hot-water blasting or extremely high-pressure jets that can gouge the material. For persistent stains, use manufacturer-approved, mild, non-solvent detergents; do not use strong ketone or chlorinated-solvent cleaners that soften PVC.

Addressing UV exposure and surface degradation

Although modern vinyl sheet piles often include UV stabilizers and pigments, long-term exposure to sunlight can cause surface chalking, loss of gloss, and in extreme cases, surface microcracking. Maintenance should focus on limiting further degradation and restoring protective properties where possible.

Surface treatment and restoration

For aesthetic restoration and minor protective improvement, apply manufacturer-recommended rejuvenators or vinyl protectants after cleaning. These products typically restore flexibility to the surface layer and improve water shedding. Any coating or protectant should be tested on a small area first and used only if it does not interfere with future welding or joining operations.

Repairing mechanical damage and interlock issues

Mechanical damage—cracks, gouges, impact dents, or deformed interlocks—must be evaluated for structural significance. Small surface scratches are generally cosmetic; deep cracks or broken interlocks compromise wall continuity and must be repaired or the affected pile replaced.

Field repair techniques

Small cracks and holes can be patched using compatible cold-applied vinyl repair kits or chemically compatible adhesives and filler compounds. For interlock repair, temporary mechanical clamps can maintain water tightness until a replacement section is installed. Welding or heat-fusion repair is possible for many PVC materials—however, only trained technicians with appropriate equipment should perform fusion welding to restore interlock or panel continuity.

Anchorage, tiebacks and structural checks

Sheet pile performance depends on the whole system—piles, anchors, backfill, and connections. Maintain anchors, deadmen, tie rods, and wales to prevent movement or rotation of the wall. Regularly verify anchor head corrosion (for metallic components), tension, and alignment. Replace sacrificial components before they fail.

Monitoring and instrumentation

Install simple monitoring devices—tape measures, sightlines, survey points—to observe displacement. In higher-risk installations, use load cells on tiebacks, inclinometers in active zones, or strain gauges. Log readings and compare with baseline to detect trends indicating anchor loss or soil movement that can overstress piles.

Preventing and managing environmental impacts

Maintenance activities around shorelines must minimize environmental harm. Use containment and silt curtains when cleaning to prevent dislodged organisms and debris from spreading. Select cleaning agents approved for aquatic use and avoid solvents that can harm marine life. Coordinate with local environmental authorities when working in protected waters.

Lifecycle management: inspection records, replacement thresholds, and budgeting

Good maintenance is as much documentation as action. Maintain an inspection log with dates, photographs, and remedial actions. Define replacement thresholds—e.g., interlock gap exceedance, vertical displacement beyond design tolerance, or crack length and depth criteria—that trigger replacement of elements rather than patching. Budget for periodic panel replacement and anchor servicing as part of asset lifecycle planning.

| Activity | Frequency (typical) | Notes |

| Visual inspection | 3–12 months | Increase frequency after storms |

| Cleaning / biofouling control | 6–24 months | Site-dependent; more often in warm, nutrient-rich waters |

| Anchor/tieback check | Annually | Load test if movement detected |

| Detailed structural review | Every 5 years | Include geotechnical reassessment |

Safety, training and contractor selection

Maintenance around water is hazardous—use trained personnel, confined space protocols for submerged work, and fall-protection systems. Choose contractors with proven experience in vinyl pile systems and ask for references, equipment lists, and method statements that demonstrate proper cleaning, welding, and lifting practices.

Conclusion: maintain to extend value and reduce risk

Vinyl sheet piles offer many advantages, but these are only realized when combined with a deliberate maintenance program: regular inspections, appropriate cleaning, timely repairs, anchor and backfill management, and rigorous documentation. A site-specific schedule, informed by exposure and loading conditions, coupled with trained crews and environmentally responsible practices will keep vinyl sheet piles performing optimally while minimizing lifecycle costs and operational risk.

English

English 中文简体

中文简体