Feb 04,2026

Marine construction projects demand materials that can withstand harsh environments, including saltwater, wave action, and fluctuating weather conditions. Vinyl sheet piles have emerged as a popular alternative to traditional steel or concrete piles due to their durability, low maintenance requirements, and cost-effectiveness. Understanding the benefits of vinyl sheet piles helps engineers, contractors, and project managers make informed choices for waterfront infrastructure, docks, seawalls, and other marine applications.

What Are Vinyl Sheet Piles?

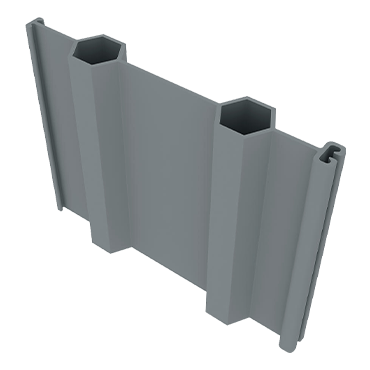

Vinyl sheet piles are interlocking panels made from high-density polyvinyl chloride (PVC) or other durable polymer materials. They are designed to be driven into soil to create retaining walls, bulkheads, or protective barriers. The interlocking design ensures a tight seal, providing stability and preventing water seepage.

Unlike traditional steel or concrete piles, vinyl sheet piles are lightweight yet strong, allowing for easier transportation and handling on construction sites. Their polymer composition makes them naturally resistant to corrosion, rot, and marine organisms, which is a critical advantage in marine environments.

Durability in Marine Environments

Vinyl sheet piles are exceptionally durable in marine applications. Exposure to saltwater, ultraviolet (UV) rays, and extreme temperatures can quickly degrade traditional steel piles through rusting or concrete piles through cracking and spalling. Vinyl materials, by contrast, are inherently resistant to these challenges, maintaining structural integrity over decades.

The non-corrosive nature of vinyl prevents damage from chemical and biological factors such as algae, barnacles, and mollusks. This resistance reduces maintenance costs and extends the lifespan of the structure, which is particularly beneficial for piers, seawalls, and other infrastructure constantly exposed to water.

Ease of Installation and Adaptability

Vinyl sheet piles are easier and faster to install compared to steel or concrete alternatives. Their lightweight design allows for installation using smaller equipment, reducing labor costs and project timelines. Interlocking systems provide secure connections, ensuring the wall remains stable under dynamic water and soil pressures.

Vinyl sheet piles can be adapted to a wide range of soil types and water depths. Customizable panel lengths and thicknesses allow engineers to design walls tailored to site-specific load and environmental conditions. Additionally, they can be cut or shaped on-site without compromising structural performance, offering significant flexibility for complex projects.

Cost-Effectiveness Compared to Traditional Materials

Although the initial material cost of vinyl sheet piles may be slightly higher than untreated steel, their long-term cost-effectiveness is substantial. Traditional steel piles require regular maintenance such as painting, coating, or replacement due to corrosion, which increases lifecycle costs. Concrete piles may need repair due to cracking or spalling from freeze-thaw cycles and water exposure.

Vinyl sheet piles eliminate most of these maintenance costs. Their resistance to corrosion and environmental degradation reduces repair and replacement frequency, offering significant savings over the life of a marine project. The ease of installation also reduces labor and equipment expenses, further enhancing cost efficiency.

Environmental Benefits of Vinyl Sheet Piles

Vinyl sheet piles are environmentally friendly, as they do not leach harmful chemicals into the water and are often recyclable at the end of their service life. Their long lifespan minimizes the need for frequent replacement, reducing the environmental impact of construction and demolition waste.

Additionally, vinyl piles’ resistance to marine organisms reduces the need for chemical treatments that are commonly used to protect steel or wooden piles, further limiting ecological disruption in sensitive marine environments.

Performance Under Load and Stress

Vinyl sheet piles are engineered to handle substantial lateral and vertical loads, making them suitable for retaining walls, bulkheads, and levees. High-density PVC provides sufficient rigidity while maintaining flexibility to absorb minor soil movements and water pressure changes, which reduces the risk of cracking or structural failure.

Their interlocking design allows for continuous wall formation, distributing stress evenly along the length of the wall. This ensures reliable performance even under dynamic loading conditions, such as tides, waves, or temporary impact from floating debris.

Maintenance Requirements and Lifespan

One of the most compelling advantages of vinyl sheet piles is their minimal maintenance requirement. Unlike steel, which must be inspected and coated regularly, or concrete, which requires patching and sealing, vinyl only needs occasional cleaning to remove algae or debris. No special coatings or treatments are required.

With proper installation, vinyl sheet piles can have a lifespan exceeding 50 years in marine environments. This longevity provides unmatched value for projects where replacement or repair access is difficult or expensive.

Comparison with Other Marine Pile Materials

| Material | Durability | Maintenance | Cost Efficiency |

| Vinyl | High, corrosion-resistant | Minimal | Very cost-effective long-term |

| Steel | Moderate, prone to rust | High, coatings and repairs needed | Lower cost initially, higher lifecycle cost |

| Concrete | Moderate, may crack over time | Medium, patching required | Moderate cost, shorter lifespan |

Conclusion: Smart Investment for Marine Projects

Vinyl sheet piles offer a compelling combination of durability, ease of installation, low maintenance, and cost-effectiveness for marine construction projects. Resistant to corrosion, chemical exposure, and marine organisms, they outperform traditional steel and concrete piles in longevity and performance. For engineers, contractors, and project owners seeking long-term value and reliable protection for docks, seawalls, and bulkheads, vinyl sheet piles represent a highly practical and sustainable solution.

English

English 中文简体

中文简体