Jan 23,2026

Vinyl (PVC and reinforced vinyl) sheet piles are an increasingly popular alternative to traditional steel and concrete for waterfront retaining walls, bulkheads, cofferdams, flood protection and lightweight retaining structures. Their corrosion resistance, low maintenance and ease of handling make them attractive — but selecting the right vinyl sheet pile system requires close attention to geotechnical, structural, environmental and constructability factors. This article provides a practical checklist and engineering guidance for professionals and owners evaluating vinyl sheet piles for a project.

Project Loads and Structural Requirements

Begin by quantifying the loads the wall must resist: lateral earth pressure (surcharge from roads or buildings), hydrostatic pressure, wave and current forces for marine sites, and live loads from cranes or vehicular traffic. Specify whether the wall will be free-standing, tied-back with anchors, waler-supported, or integrated into a composite structure. Vinyl profiles have lower flexural stiffness than steel, so wall geometry, embedment depth and anchoring (deadman or tieback) are crucial to limit deflections and overturning.

Design serviceability vs strength

Because vinyl is more flexible, serviceability criteria such as maximum lateral deflection (mm or percent of exposed height) often control design more than ultimate strength. Establish allowable deflection limits up front and select profile strength (moment of inertia) and spacing consistent with those limits under expected loads.

Soil Conditions and Geotechnical Compatibility

Soil type, groundwater conditions, and the presence of coarse fill or boulders directly affect pile selection and installation method. Cohesive clays impose different embedment and skin-friction behavior than granular sands. For malleable soils with high lateral pressure, choose deeper embedment or tieback systems. If cobbles or debris exist, plan for pre-drilling, vibration constraints, or alternative foundations because vinyl can be damaged by impact during driving.

Bearing capacity and settlement

Consider settlement of the supported structures and potential consolidation under surcharge loads. Vinyl walls typically transfer loads to passive resistance in the soil and to anchors; evaluate long-term consolidation and pore-pressure dissipation to avoid late movement.

Environmental Exposure and Chemical Resistance

One of vinyl’s strengths is corrosion resistance to aerobic and anaerobic marine environments where steel would require sacrificial coatings and maintenance. However, vinyl’s chemical compatibility must be checked when the wall faces aggressive environments—petroleum hydrocarbons, solvents, concentrated acids or alkalis, or high concentrations of chlorides can affect some polymer formulations. Select grades tested for the specific chemical exposures expected on site and request manufacturer compatibility data.

UV, Temperature and Long-Term Durability

Exposure to sunlight, high temperatures and freeze–thaw cycles influence long-term performance. Ensure the vinyl compound includes UV stabilizers and has been engineered for the local climate. Some reinforced vinyl composites include additives and fillers to improve creep resistance and dimensional stability at elevated temperatures. Ask for accelerated-aging test results that demonstrate retention of tensile and flexural properties over the design life (commonly 25–50 years).

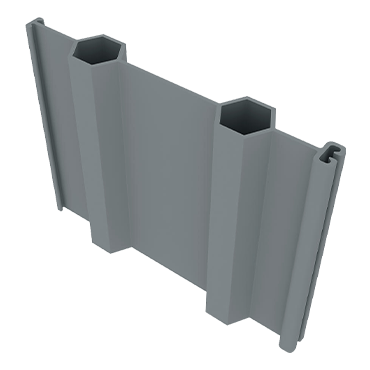

Profile Geometry and Interlock Design

Vinyl sheet piles come in multiple profile shapes (U, Z, tongue-and-groove, and proprietary interlocks). Interlock type affects ease of driving, watertightness, and rotational stiffness. A robust mechanical interlock minimizes leakage and distributes bending across sections, while lock geometry impacts the capacity to accommodate thermal movement. Choose profiles with proven interlock durability and specify connection tolerances if welding or mechanical fastening to steel components is required.

Installation Method and Site Constraints

Installation options include vibratory hammers, impact hammers with cushioned leads, hydraulic pressing, and drilled-and-grouted anchors for reinforcement. Vinyl is susceptible to impact damage; therefore select installation methods that match substrate conditions and minimize risk (e.g., vibratory driving for granular soils, pressing for sensitive sites). Consider on-site access for cranes or installers, noise and vibration limits, tidal windows for marine work, and available working platforms.

Avoiding damage during driving

Use sacrificial driving heads, soft cushions, or pre-bore in compacted fills to prevent cracking. Verify driving energy and sequences with the supplier’s guidance and perform test drives to confirm expected penetration rates and pile alignment.

Watertightness and Joint Sealing

If the application requires a watertight bulkhead, evaluate interlock tightness and the need for supplemental seals such as rubber gaskets or field-applied sealants. For flood protection, combined use of interlock seals and backfill compression can reduce leakage. For retention of fines or liquids, specify interlocks that are rated for hydraulic head and provide performance data under pressure.

Anchoring, Tiebacks and Structural Integration

Vinyl sheet piles are often used with anchors (deadman, ground anchors, or tieback rods) when heights or lateral loads exceed what a free-standing wall can safely resist. Determine anchor capacity, corrosion protection for tendon materials, and anchor installation angles. Coordinate design of anchor heads, walers and cap beams to distribute loads and allow for adjustment during installation.

Constructability, Handling and Logistics

Vinyl piles are lighter than steel which simplifies handling and reduces crane capacity and transportation cost, but they require careful storage to prevent UV degradation or distortion. Inspect on-delivery for straightness, interlock damage and verify length tolerances. Plan for material staging to maintain tide and access windows on marine projects.

Life-Cycle Cost, Maintenance and Sustainability

Perform a life-cycle cost analysis comparing initial material and installation costs with long-term maintenance: vinyl’s low-maintenance profile (no regular coating or cathodic protection) often yields lower total cost of ownership in corrosive environments. Also consider end-of-life disposal or recyclability and whether the product contains recycled content or meets local sustainability targets.

Standards, Testing and Supplier Qualifications

Require material datasheets, test certificates (tensile, flexural, creep, impact, UV aging, and chemical resistance), and references for similar installed projects. Check compliance with local building codes and marine standards. Evaluate the supplier’s technical support, availability of custom profiles, warranty terms, and ability to provide on-site installation guidance or trained installers.

| Factor | What to Check | Why It Matters |

| Soil & groundwater | Borehole logs, fines, boulder risk | Drives installation method and embedment |

| Load cases | Surcharge, wave, hydrostatic pressures | Controls section modulus and anchoring |

| Chemical/UV exposure | Compatibility charts, accelerated tests | Ensures long-term durability |

| Installation constraints | Access, vibration limits, tidal windows | Determines practical driving method |

Conclusion

Vinyl sheet piles offer clear advantages in corrosion-prone and low-maintenance projects, but their success hinges on matching product properties and installation method to site-specific geotechnical, structural and environmental requirements. Early coordination between geotechnical engineers, structural designers and experienced vinyl suppliers—combined with test driving, material certification and a well-defined anchoring and watertightness strategy—will minimize risk and deliver durable, cost-effective retaining solutions.

English

English 中文简体

中文简体