Feb 04,2026

PVC sheet piles are modular interlocking sheets made from polyvinyl chloride designed for retaining walls, flood protection, and soil stabilization in construction projects. They are widely used for marine works, embankments, retaining structures, and other civil engineering applications. The material's lightweight nature, corrosion resistance, and ease of installation make it a preferred alternative to steel or concrete in many scenarios.

Understanding PVC sheet piles involves analyzing their mechanical properties, installation methods, performance in different environments, and the benefits they offer over traditional materials.

Material Properties of PVC Sheet Piles

PVC sheet piles are engineered to provide strength, flexibility, and long-term durability. The material’s polymer structure ensures resistance to corrosion, chemical attack, and weathering.

Mechanical Characteristics

- High tensile strength to resist bending and soil pressure

- Flexibility to absorb ground movements without cracking

- Lightweight for easier handling and transport

Environmental Resistance

PVC is naturally resistant to corrosion from water, chemicals, and salt, making it suitable for marine and industrial environments. Unlike steel, PVC sheet piles do not require protective coatings or galvanization.

- Resistant to rust and algae growth

- UV-stabilized formulations prevent degradation from sunlight exposure

- Chemical resistance against acidic or alkaline soils

Applications of PVC Sheet Piles

PVC sheet piles are versatile and can be employed in a range of construction scenarios where traditional materials may face limitations. Their light weight and durability make them ideal for both temporary and permanent installations.

Marine and Waterfront Projects

- Harbor walls and docks

- Erosion control and shoreline stabilization

- Flood barrier construction

Civil Engineering and Retaining Structures

- Retaining walls for roadways and embankments

- Trench and excavation shoring

- Soil stabilization and slope protection

Installation Techniques for PVC Sheet Piles

Proper installation is critical for the performance and longevity of PVC sheet piles. They can be installed using traditional piling equipment or light machinery depending on the project scale.

Driving Methods

- Vibratory hammers for rapid installation with minimal soil disturbance

- Hydraulic pressing for delicate environments or sensitive soil types

- Lightweight hammering for temporary or small-scale projects

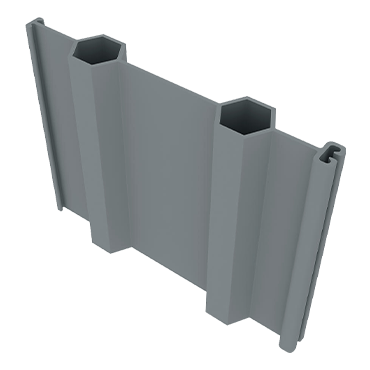

Interlocking Design

PVC sheet piles feature interlocking profiles that allow multiple sheets to connect seamlessly, creating a continuous wall. This interlocking mechanism ensures structural integrity, watertightness, and resistance to lateral soil pressure.

Advantages of PVC Sheet Piles Over Traditional Materials

PVC sheet piles offer several advantages compared to steel or concrete piles, making them an attractive alternative for many construction projects.

| Feature | PVC Sheet Piles | Steel Sheet Piles | Concrete Sheet Piles |

| Corrosion Resistance | High | Low | Medium |

| Weight | Light | Heavy | Very Heavy |

| Ease of Installation | Easy | Moderate | Difficult |

| Maintenance | Low | Medium | Medium |

Environmental and Sustainability Considerations

PVC sheet piles are environmentally friendly compared to steel, which requires significant energy for production and is prone to corrosion, or concrete, which has a high carbon footprint. Additionally, PVC is recyclable, and the piles’ lightweight nature reduces transport energy.

Conclusion

PVC sheet piles are an innovative and efficient solution for retaining walls, flood barriers, and soil stabilization. Their corrosion resistance, lightweight design, easy installation, and long-term durability make them ideal for a variety of construction projects. By understanding material properties, installation methods, and applications, engineers and construction professionals can select the most suitable PVC sheet piles for reliable and cost-effective results.

English

English 中文简体

中文简体