Jan 23,2026

Vinyl sheet piles are interlocking, high-density PVC profiles used in marine, civil, and environmental construction to create retaining walls, seawalls, and erosion control structures. Unlike traditional steel or concrete sheet piles, vinyl sheet piles are lightweight, corrosion-resistant, and require less maintenance. They are commonly used in shoreline stabilization, waterfront landscaping, flood protection, and temporary cofferdams where long-term durability and low upkeep are essential. The interlocking design ensures a continuous barrier that resists water pressure and soil movement while allowing for flexibility under load.

Key Advantages of Vinyl Sheet Piles

Vinyl sheet piles offer several benefits that make them attractive for many construction projects, especially in harsh environments where corrosion and maintenance costs are major concerns. Their lightweight nature reduces transportation and installation costs, while their resistance to saltwater, chemicals, and UV exposure ensures long-term performance. Additionally, vinyl sheet piles can be engineered to match specific project requirements, including different wall heights, soil types, and load conditions.

Corrosion Resistance and Longevity

One of the most significant advantages of vinyl sheet piles is their resistance to corrosion, which is a common issue for steel piles in marine and industrial environments. PVC does not rust, and with proper UV stabilization, it maintains structural integrity over decades. This makes vinyl sheet piles especially suitable for coastal applications where saltwater and wet conditions accelerate deterioration of metal structures.

Lightweight and Easy Handling

Vinyl sheet piles are significantly lighter than steel, which simplifies handling and reduces the need for heavy lifting equipment. This can speed up installation and reduce labor costs. In areas with limited access or tight spaces, lightweight sheet piles offer a practical advantage because they can be maneuvered more easily and installed with smaller machinery.

Typical Applications of Vinyl Sheet Piles

Vinyl sheet piles are versatile and can be used in a wide range of projects. They are particularly well-suited for environments where corrosion resistance and aesthetic appearance are important. Below are common applications where vinyl sheet piles are frequently chosen.

Shoreline Protection and Seawalls

In coastal areas, vinyl sheet piles are used to build seawalls that protect shorelines from erosion, wave action, and storm surges. Their flexibility allows them to absorb and distribute wave energy, reducing the risk of structural failure. They can also be used for waterfront landscaping to create clean, durable edges around marinas, docks, and residential properties.

Flood Control and Retaining Walls

Vinyl sheet piles are effective for flood control structures such as levees, floodwalls, and temporary cofferdams. Their interlocking design forms a continuous barrier that can resist hydraulic pressure and prevent water seepage. When combined with proper anchoring and backfill, vinyl sheet piles can create strong, reliable retaining walls for both permanent and temporary installations.

Environmental and Wetland Projects

Because vinyl is chemically inert and does not leach harmful substances, it is often used in environmental projects such as wetland restoration, erosion control, and containment systems. Vinyl sheet piles can provide stable barriers without negatively impacting surrounding ecosystems, making them a preferred choice for environmentally sensitive areas.

How Vinyl Sheet Piles Are Installed

The installation process for vinyl sheet piles is generally simpler than that of steel or concrete. However, proper site assessment and preparation are crucial to ensure stability and performance. Installation typically involves driving the interlocking piles into the ground using vibratory hammers, hydraulic presses, or impact hammers, depending on soil conditions and wall requirements.

Site Preparation and Soil Assessment

Before installation, the site must be evaluated for soil type, groundwater level, and load requirements. Soil tests help determine the appropriate pile length and driving method. For soft soils, longer piles or additional anchoring may be required to achieve sufficient embedment and resistance to lateral forces.

Driving Methods and Equipment

Vinyl sheet piles can be driven using several methods. Vibratory hammers are commonly used for softer soils, while hydraulic presses are suitable for precise installation with minimal vibration. In harder soils, impact hammers may be necessary, but care must be taken to avoid damaging the PVC material. Proper driving techniques and equipment selection are essential to prevent cracking or deformation during installation.

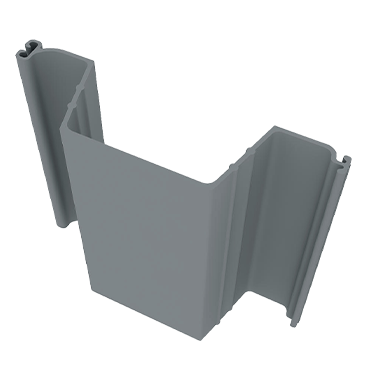

Selecting the Right Vinyl Sheet Pile Type

Vinyl sheet piles come in various profiles, thicknesses, and lengths. Choosing the right type depends on the project’s load requirements, soil conditions, and environmental factors. Engineers often calculate bending moment, lateral pressure, and embedment depth to select the appropriate pile design. Below is a practical comparison of common vinyl sheet pile options.

| Profile Type | Wall Height | Recommended Use | Typical Soil |

| Standard Interlock | Up to 3m | Residential seawalls | Soft to medium |

| Heavy-Duty | 3m to 6m | Commercial waterfront | Medium to hard |

| Extra-Heavy | 6m+ | Industrial floodwalls | Hard or mixed |

Maintenance and Lifespan Expectations

Vinyl sheet piles are known for their low maintenance and long service life. With proper installation and regular inspection, they can last for decades without significant degradation. Unlike steel, vinyl does not corrode, and it is resistant to chemicals and UV exposure. However, the structural performance can still be affected by physical damage, improper driving, or extreme load conditions.

Routine Inspection Checklist

- Check for cracks, splits, or deformation along the piles

- Inspect interlock joints for separation or misalignment

- Monitor for excessive movement or settlement

- Verify that drainage and backfill are stable and not eroding

Typical Lifespan Factors

The lifespan of vinyl sheet piles depends on exposure conditions and structural loading. In marine environments with strong wave action, the piles may experience higher stress and require more frequent inspection. However, in calm water and low-load applications, vinyl sheet piles can easily exceed 50 years with minimal maintenance. Proper UV stabilization and quality manufacturing are key factors that determine longevity.

Conclusion: When Vinyl Sheet Piles Are the Best Choice

Vinyl sheet piles offer a modern, cost-effective alternative to steel and concrete for many shoreline and retaining wall projects. Their corrosion resistance, lightweight handling, and long lifespan make them ideal for coastal, environmental, and residential applications. While they may not be suitable for extremely high-load or deep-water structures, vinyl sheet piles provide excellent performance in many common scenarios. By selecting the correct profile, ensuring proper installation, and maintaining regular inspections, project owners can achieve durable, low-maintenance, and visually appealing waterfront structures.

English

English 中文简体

中文简体