Feb 10,2026

Understanding Vinyl Sheet Pile Systems

Vinyl sheet piles represent an innovative alternative to traditional steel sheet piling for waterfront construction and earth retention applications. These interlocking panels, manufactured from polyvinyl chloride (PVC) compounds reinforced with internal structural elements, provide corrosion-free performance in marine and freshwater environments. Unlike steel that deteriorates from rust and galvanic corrosion, vinyl sheet piles maintain structural integrity throughout their service life without protective coatings or cathodic protection systems. The material's inherent resistance to saltwater, acids, alkalis, and biological organisms makes it particularly valuable for coastal construction, bulkheads, seawalls, and erosion control projects.

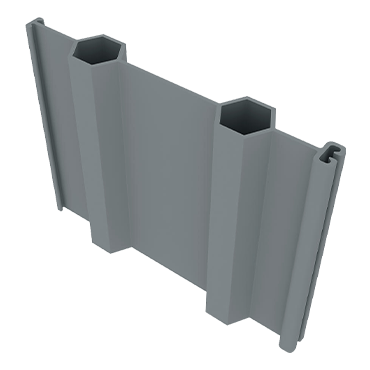

Modern vinyl sheet pile systems feature sophisticated designs incorporating internal reinforcement chambers, UV stabilizers, and engineered interlocking joints that ensure watertight connections between adjacent panels. Manufacturers produce various profiles including Z-shapes, flat wall panels, and custom configurations tailored to specific load requirements and installation conditions. The lightweight nature of vinyl compared to steel simplifies handling and installation while reducing equipment requirements and associated costs. With proper design and installation, vinyl sheet piles deliver decades of maintenance-free service in applications where corrosion resistance and long-term durability outweigh the higher load-bearing capacity of steel alternatives.

Steel Sheet Pile Fundamentals

Steel sheet piles have served as the industry standard for heavy-duty earth retention and marine construction for over a century. These rolled steel sections feature interlocking edges that connect adjacent piles, forming continuous walls capable of resisting substantial lateral earth pressures and water loads. Common profiles include U-shaped, Z-shaped, and straight web configurations, each offering different section modulus values and load-bearing capacities. Hot-rolled steel sheet piles range from lightweight AZ-12 sections suitable for temporary applications to heavy AZ-48 and PZC sections supporting permanent structures with demanding loading conditions.

The primary advantage of steel sheet piles lies in their exceptional strength-to-thickness ratio, enabling them to support significant loads while maintaining relatively slender wall thicknesses. This characteristic proves essential for deep excavations, cofferdams, bridge abutments, and permanent waterfront structures where soil and hydrostatic pressures exceed vinyl's structural capacity. However, steel's susceptibility to corrosion in marine environments necessitates protective measures including hot-dip galvanizing, epoxy coatings, or increased thickness to accommodate corrosion allowances. These protective strategies add initial costs and may require periodic maintenance to ensure long-term structural integrity in aggressive environments.

Comprehensive Material Comparison

| Property | Vinyl Sheet Piles | Steel Sheet Piles |

| Weight | 8-15 lbs/linear ft | 25-75 lbs/linear ft |

| Corrosion Resistance | Excellent, no corrosion | Poor without protection |

| Service Life | 75-100+ years | 30-50 years (unprotected) |

| Maximum Height | 8-12 feet typical | 30+ feet |

| Maintenance | Minimal to none | Coating renewal required |

| Installation Equipment | Light machinery, manual | Vibratory hammers, cranes |

| Temperature Resistance | -40°F to 140°F | -60°F to 1000°F+ |

Structural Capacity Differences

The fundamental distinction between vinyl and steel sheet piles centers on load-bearing capacity and allowable wall heights. Steel's superior strength enables walls exceeding 30 feet in retained height supporting substantial surcharge loads from buildings, equipment, or traffic. Vinyl sheet piles typically limit applications to walls under 12 feet with moderate lateral pressures from residential fill or light commercial loads. This capacity difference stems from material properties where steel's tensile strength of 36,000-50,000 psi dramatically exceeds vinyl's 6,000-8,000 psi. Engineers must carefully evaluate project-specific soil conditions, water levels, and loading requirements to determine which material provides adequate structural performance with appropriate safety factors.

Environmental Performance and Longevity

Vinyl sheet piles excel in harsh environments where steel faces accelerated deterioration. Marine applications with saltwater exposure cause severe corrosion on unprotected steel, requiring expensive coatings or oversized sections accounting for metal loss over time. Vinyl remains chemically inert to saltwater, brackish water, sewage, and most industrial chemicals, maintaining full structural capacity indefinitely without protective treatments. The material resists marine borers, barnacle attachment, and biological fouling that plague both treated and untreated steel. UV stabilizers incorporated in vinyl formulations prevent degradation from continuous sunlight exposure, ensuring performance in above-water applications. This durability translates to lifecycle cost advantages despite higher initial material expenses in many marine and waterfront projects.

Cost Analysis and Economic Considerations

Initial Material and Installation Costs

Vinyl sheet pile material costs typically range from $45 to $85 per linear foot depending on panel height, profile design, and order quantity. Steel sheet piles cost $30 to $120 per linear foot based on section modulus, coating requirements, and current steel market prices. While vinyl material prices may appear higher for comparable wall heights, installation cost differentials often favor vinyl significantly. The lightweight panels allow manual handling or small equipment operation, reducing labor hours and eliminating expensive pile-driving equipment rental. A typical vinyl installation crew of 2-3 workers accomplishes 40-60 linear feet daily using excavators or manual driving methods. Steel installation requires vibratory hammers, cranes, and specialized crews achieving 30-50 linear feet daily at substantially higher equipment and labor rates.

Lifecycle Cost Comparison

Total project costs must account for long-term maintenance and replacement expenses beyond initial construction. Steel sheet piles in marine environments require coating renewal every 15-25 years depending on exposure severity and coating quality. Recoating costs including surface preparation, containment, and application range from $15 to $40 per square foot of exposed wall area. Corrosion-induced structural failures necessitate complete replacement after 30-50 years in aggressive environments. Vinyl sheet piles require virtually no maintenance beyond occasional cleaning, with expected service lives exceeding 75-100 years. Present value analysis comparing initial costs against maintenance and replacement expenses over 50-75 year periods frequently demonstrates vinyl's economic advantages despite higher upfront investment, particularly in saltwater applications where steel corrosion proceeds rapidly.

Installation Methods and Techniques

Vinyl Sheet Pile Installation Process

Installing vinyl sheet piles begins with accurate surveying and layout establishing precise alignment for the completed wall. Excavation creates a trench along the wall alignment, typically 12-18 inches wide and extending to the planned pile tip elevation. Installers position the first panel vertically in the trench, ensuring plumb alignment using levels and bracing. Subsequent panels connect through interlocking joints, with installers carefully engaging the joint profile along the full panel height before driving. Driving methods include vibratory plate compactors for loose soils, hydraulic rams for firmer materials, or water jetting in sandy conditions. Panels advance to design depth where bearing capacity or depth requirements are satisfied. Backfilling proceeds in lifts with compaction equipment, applying fill evenly on both wall sides to prevent deflection during construction.

Steel Sheet Pile Installation Procedures

Steel sheet pile installation demands heavier equipment and more rigorous control procedures. Thread individual piles through templates or walers maintaining precise alignment and verticality throughout the driving sequence. Vibratory hammers generate high-frequency vibrations that fluidize soil around the pile toe, reducing driving resistance while advancing piles to design depth. Impact hammers deliver repeated blows for dense soils or driving to bedrock, though vibration and noise often restrict their use in urban areas. Pile driving analyzers monitor driving resistance and energy transfer, verifying adequate bearing capacity and detecting potential damage during installation. Interlock integrity receives careful attention as driving stresses can separate adjacent piles, requiring welding or mechanical reconnection to maintain wall continuity and prevent soil or water infiltration.

Optimal Applications for Each Material

Best Uses for Vinyl Sheet Piles

Vinyl sheet piles excel in applications prioritizing corrosion resistance and long-term durability over maximum structural capacity. Ideal projects include residential waterfront bulkheads protecting shoreline properties from erosion while providing boat docking facilities. The material suits marina construction where saltwater exposure and aesthetic considerations favor maintenance-free solutions. Lake and pond retention walls benefit from vinyl's ability to withstand freeze-thaw cycles without cracking or spalling. Residential retaining walls under 8 feet high supporting landscaping or terraced yards use vinyl for permanent, attractive installations. Erosion control along streams and rivers employs vinyl where moderate flow velocities require bank stabilization without heavy structural loads. Wastewater and industrial applications with chemical exposure utilize vinyl's chemical resistance where steel would corrode rapidly.

Optimal Steel Sheet Pile Applications

Steel sheet piles remain essential for heavy-duty applications exceeding vinyl's structural limitations. Deep excavations for building foundations, underground parking, or subway construction require steel's strength supporting 20-40 foot wall heights with heavy surcharge loads. Permanent flood protection barriers defending against major river flooding or storm surge need steel's capacity resisting extreme hydrostatic pressures. Bridge abutments and highway retaining walls supporting roadway embankments and traffic loads rely on steel's proven performance under Department of Transportation specifications. Cofferdams for marine construction provide dry work areas by excluding water through steel sheet pile cells or cellular structures impossible with vinyl. Brownfield sites with contaminated soils use steel where unknown subsurface conditions might include debris or obstructions that could damage vinyl during driving.

Design Considerations and Engineering Requirements

Proper sheet pile selection and design requires comprehensive geotechnical investigation and structural analysis ensuring adequate performance with appropriate safety margins.

- Soil conditions determine driving feasibility and required embedment depth. Cohesive clays allow shallower embedment than cohesionless sands requiring passive resistance development. Subsurface explorations identify soil stratigraphy, strength parameters, and groundwater levels essential for accurate design.

- Loading analysis quantifies lateral earth pressures using Rankine or Coulomb theories, incorporating soil friction angles, cohesion, and surcharge loads from adjacent structures or equipment. Hydrostatic pressures from groundwater or surface water add to total lateral loads requiring resistance.

- Structural capacity verification ensures selected sheet pile sections resist maximum bending moments without exceeding allowable stresses or deflection limits. Vinyl designs must account for temperature-dependent modulus values and long-term creep under sustained loading.

- Anchorage systems including tiebacks, deadman anchors, or internal bracing may be necessary when cantilevered walls cannot achieve adequate stability. Anchor design coordinates with sheet pile selection ensuring compatible load transfer and constructability.

- Construction sequencing affects loading and stability during installation. Phased excavation and backfilling procedures prevent excessive deflections or failure during construction before the completed system develops full resistance capacity.

Maintenance and Long-Term Performance

Vinyl Maintenance Requirements

Vinyl sheet pile walls require minimal maintenance throughout their service life. Periodic inspections every 3-5 years verify wall alignment, check for settlement or movement, and assess overall condition. Cleaning removes accumulated organic matter, algae, or sediment using pressure washing or soft brushes with mild detergent solutions. Unlike steel, vinyl never requires coating renewal, rust treatment, or corrosion repair. Minor damage from impacts or abrasion can be repaired using PVC welding techniques or mechanical fasteners depending on severity. The primary maintenance consideration involves monitoring backfill settlement and ensuring proper drainage prevents hydrostatic pressure buildup behind walls. With appropriate initial design and installation quality, vinyl walls deliver decades of trouble-free performance without significant maintenance expenses.

Steel Maintenance Programs

Steel sheet pile walls in marine or corrosive environments demand active maintenance programs preserving structural integrity. Annual inspections document coating condition, identifying areas where corrosion has initiated or accelerated. Underwater inspection using divers or remote cameras examines submerged portions where corrosion often proceeds most rapidly. Coating repairs address damaged areas before extensive corrosion develops, involving surface preparation, priming, and topcoat application. Cathodic protection systems require monitoring and maintenance ensuring adequate current delivery preventing corrosion. Severely corroded sections may need supplemental strengthening through weld-on reinforcement or complete panel replacement in extreme cases. These ongoing maintenance requirements represent substantial lifecycle costs that must be factored into material selection decisions for permanent installations.

Choosing between vinyl and steel sheet piles requires careful evaluation of project-specific requirements balancing structural demands, environmental conditions, and economic constraints. Vinyl offers superior corrosion resistance and low maintenance for moderate-height walls in aggressive environments, while steel provides essential strength for demanding applications exceeding vinyl's capacity. Understanding the distinct characteristics, installation methods, and lifecycle considerations of each material enables engineers and owners to select optimal solutions delivering reliable long-term performance. As material technology continues advancing, both vinyl and steel sheet piling systems will evolve, offering increasingly sophisticated options for earth retention and marine construction challenges.

English

English 中文简体

中文简体