Feb 28,2026

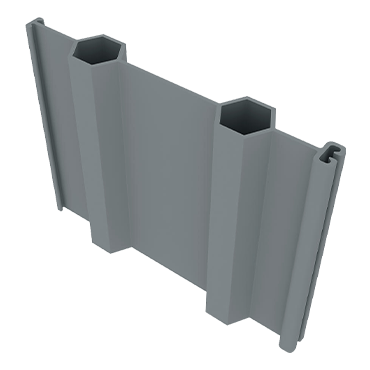

A vinyl sheet pile wall is a type of retaining and containment structure made from interlocking vinyl or PVC profiles that are driven into the ground to form a continuous barrier. Unlike traditional sheet pile walls made of steel, concrete, or timber, vinyl sheet piles rely on advanced polymer materials that offer corrosion resistance, lightweight handling, and long-term durability in harsh environments.

These walls are commonly used in waterfront, coastal, and environmental applications where soil retention, erosion control, or water containment is required. The interlocking design allows individual vinyl sheet piles to connect tightly, creating a wall that resists lateral soil pressure while preventing soil migration and water seepage.

Vinyl sheet pile walls are not typically designed to bear heavy structural loads like building foundations. Instead, they are optimized for earth retention, shoreline stabilization, and separation of land and water under moderate loading conditions.

Core Materials and Structural Characteristics

Vinyl sheet piles are manufactured from high-grade polyvinyl chloride (PVC) compounds that are engineered for outdoor and submerged use. These compounds are formulated to resist ultraviolet radiation, chemical exposure, and biological degradation, making them suitable for long-term installation in marine and soil environments.

Key material characteristics include:

- High resistance to corrosion, rust, and rot

- Stable performance in saltwater and freshwater environments

- Lightweight profiles that simplify transport and installation

- Engineered interlocks that maintain wall continuity

Structurally, vinyl sheet pile walls rely on their embedded depth, interlock strength, and soil interaction to resist lateral forces. In many projects, additional anchoring systems or deadman anchors are used to enhance stability when higher loads are anticipated.

How a Vinyl Sheet Pile Wall Works in Practice

Once installed, a vinyl sheet pile wall acts as a vertical barrier that separates two zones with different elevation or material properties. On waterfront projects, one side of the wall retains soil while the other side is exposed to water. On land-based projects, the wall may separate different soil layers or protect slopes from erosion.

The interlocking joints prevent soil washout while allowing the wall to flex slightly under load. This flexibility is an advantage in environments subject to temperature changes, minor ground movement, or wave action, as it reduces the likelihood of cracking or structural failure.

Main Uses of Vinyl Sheet Pile Walls

Vinyl sheet pile walls are used across a wide range of civil, environmental, and marine projects. Their versatility makes them especially attractive where long service life and low maintenance are priorities.

Shoreline and Coastal Erosion Control

One of the most common uses of vinyl sheet pile walls is shoreline stabilization. They are installed along lakes, rivers, canals, and coastal areas to prevent soil erosion caused by waves, currents, and fluctuating water levels. The wall retains the shoreline material while maintaining a clean, defined edge.

Flood Protection and Water Management

In flood-prone areas, vinyl sheet pile walls are used to create barriers that help control water flow and reduce flood damage. They can be integrated into levees, embankments, and drainage systems to reinforce soil structures and limit seepage during high-water events.

Retaining Walls for Light to Medium Loads

Vinyl sheet pile walls serve as effective retaining walls for landscaping projects, access roads, and light infrastructure. They are particularly useful where space is limited, as they require minimal footprint compared to sloped embankments.

Environmental Containment and Remediation

Environmental projects often use vinyl sheet piles to isolate contaminated soil or sediments. The low permeability of interlocked vinyl profiles helps prevent the spread of pollutants, making them suitable for remediation sites and environmental protection zones.

Typical Applications by Project Type

| Project Type | Primary Purpose | Why Vinyl Sheet Piles Are Used |

| Waterfront Development | Soil retention | Corrosion resistance and long service life |

| Canal and Riverbanks | Erosion control | Low maintenance in wet environments |

| Landscaping Projects | Grade separation | Lightweight and easy installation |

| Environmental Barriers | Containment | Tight interlocks reduce soil migration |

Advantages Compared to Traditional Sheet Pile Walls

Vinyl sheet pile walls offer several practical advantages over steel, timber, and concrete alternatives. These benefits often translate into lower lifecycle costs and fewer maintenance concerns.

- No corrosion, even in saltwater or chemically aggressive soils

- Reduced installation equipment requirements due to lightweight profiles

- Minimal maintenance over the wall’s service life

- Cleaner appearance suitable for residential and public areas

Design Considerations for Vinyl Sheet Pile Walls

Proper design is essential to ensure a vinyl sheet pile wall performs as intended. Engineers must evaluate soil conditions, water levels, loading requirements, and wall height before selecting a profile and installation method.

Key design factors include embedment depth, expected lateral pressure, and whether additional anchoring is required. In higher-load scenarios, vinyl sheet piles may be combined with tie-back systems or used alongside other structural elements.

Installation Process Overview

Installation typically involves driving the vinyl sheet piles into the ground using vibratory hammers or press-in methods. The lightweight nature of vinyl reduces noise and vibration compared to steel piles, which is beneficial in residential or environmentally sensitive areas.

Careful alignment during installation ensures proper interlocking and wall continuity. Once installed, the wall can be backfilled, capped, or finished depending on the project’s aesthetic and functional requirements.

Long-Term Performance and Maintenance

One of the strongest advantages of vinyl sheet pile walls is their long-term performance with minimal maintenance. Unlike steel, vinyl does not require coatings or corrosion protection. Routine inspections are usually sufficient to ensure continued performance.

When properly designed and installed, a vinyl sheet pile wall can provide decades of reliable service, making it a cost-effective and practical solution for many earth retention and water control applications.

English

English 中文简体

中文简体