Dec 05,2025

PVC sheet piles have become an increasingly popular alternative to traditional materials like steel, concrete, and timber in various civil engineering, marine, and environmental protection projects. Their performance in terms of strength, durability, and corrosion resistance has made them a preferred choice for seawalls, retaining structures, riverbanks, and flood protection systems. As global construction trends shift toward sustainable, low-maintenance, and cost-effective materials, understanding how PVC sheet piles perform under challenging environmental conditions is essential for engineers, developers, and project planners.

This article explores the mechanical performance, long-term durability, and superior corrosion resistance of PVC sheet piles, along with their advantages and limitations compared to conventional alternatives.

1. Overview of PVC Sheet Piles

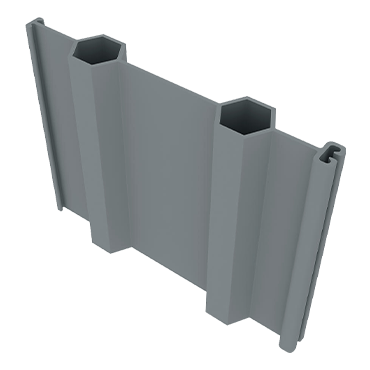

PVC sheet piles are interlocking profiles made from polyvinyl chloride (PVC), a thermoplastic polymer known for its excellent resistance to chemicals, moisture, and UV exposure. They are typically extruded into various shapes and sizes to meet different structural requirements.

Unlike steel or concrete piles, PVC sheet piles are lightweight, easy to handle, and do not require special heavy machinery for installation. They are often used for:

- Seawalls and bulkheads

- River and canal embankments

- Retaining walls

- Flood protection barriers

- Containment systems for contaminated soils or wastewater

The combination of cost-effectiveness, environmental performance, and mechanical reliability makes PVC sheet piles a compelling option in both temporary and permanent structures.

2. Mechanical Strength of PVC Sheet Piles

When evaluating the structural integrity of PVC sheet piles, strength is one of the most important factors. While PVC is not as strong as steel or reinforced concrete, modern composite formulations and profile designs have significantly enhanced its load-bearing capacity.

(1) Tensile and Flexural Strength

PVC sheet piles are typically made from high-modulus unplasticized PVC (uPVC), which offers a good balance between rigidity and flexibility. Their tensile strength generally ranges from 45–55 MPa, and flexural strength from 70–80 MPa, depending on the grade and manufacturing process.

This level of strength is sufficient for low- to medium-load applications such as:

- Small- to medium-height retaining walls

- Riverbank stabilization

- Landscape or garden retaining barriers

In large-scale projects where lateral soil pressure or hydrostatic loads are higher, engineers often use hybrid systems — combining PVC piles with steel reinforcements or anchoring systems to enhance performance.

(2) Modulus of Elasticity

PVC’s modulus of elasticity (about 3,000 MPa) is lower than steel (200,000 MPa), meaning it will deform more under the same load. However, this flexibility is advantageous in many scenarios. The slight deflection of PVC sheet piles allows them to absorb impact energy from waves or soil movements without cracking or permanent deformation.

(3) Structural Design Considerations

PVC sheet piles are typically used for applications where static loads dominate rather than heavy dynamic or vertical loads. When properly designed with adequate embedment depth, anchoring, and interlocking systems, PVC sheet piles can effectively resist lateral earth and hydrostatic pressures, ensuring stability and long-term serviceability.

3. Durability of PVC Sheet Piles

Durability refers to the ability of a material to maintain its structural and functional properties over time, despite environmental and mechanical stresses. PVC sheet piles excel in this area due to their inherent resistance to degradation mechanisms that typically affect metals, wood, and concrete.

(1) Resistance to Rot and Biological Attack

PVC is inherently inorganic and non-porous, meaning it does not absorb moisture or provide a substrate for fungi, bacteria, or marine organisms. This makes it immune to biological decay, rot, and marine borer attacks, which commonly degrade timber and certain composites.

(2) Resistance to UV and Weathering

Modern PVC sheet piles incorporate UV stabilizers and anti-aging additives that prevent the material from becoming brittle under prolonged sunlight exposure. Even in harsh coastal or tropical climates, these additives ensure color retention and mechanical integrity for decades.

Long-term field tests have shown that high-quality PVC sheet piles can last 50 years or more with minimal degradation when exposed to outdoor conditions.

(3) Impact and Fatigue Resistance

Although PVC is lighter and more flexible than traditional piling materials, it possesses good impact resistance, especially at moderate temperatures. This flexibility allows it to withstand minor ground shifts, vibrations, and impacts without cracking — a crucial feature for coastal and marine installations where water and wave pressure fluctuate continuously.

(4) Maintenance-Free Performance

Unlike steel sheet piles, which require regular painting or galvanization to prevent rust, PVC sheet piles need virtually no maintenance. There is no corrosion or oxidation, no coating wear, and no need for periodic treatment, which translates to significant lifecycle cost savings.

4. Corrosion Resistance: The Key Advantage

Perhaps the most significant benefit of PVC sheet piles is their outstanding resistance to corrosion. In environments where metal or concrete piles deteriorate quickly, PVC offers a long-term, sustainable solution.

(1) Resistance to Chemical Corrosion

PVC is highly resistant to a wide range of acids, alkalis, and salts commonly found in seawater, wastewater, and industrial environments. This makes it ideal for:

- Marine structures exposed to saltwater

- Wastewater treatment plants

- Chemical containment barriers

- Agricultural irrigation and drainage systems

In contrast, steel piles often require expensive coatings or cathodic protection systems to survive in these conditions, while concrete can suffer from chloride-induced corrosion of reinforcement bars. PVC eliminates these concerns entirely.

(2) Resistance to Electrochemical Reactions

PVC is non-conductive, meaning it is immune to electrochemical corrosion processes such as galvanic corrosion, which commonly affect metal structures in contact with dissimilar materials or moist soils.

This property makes PVC sheet piles particularly suitable for use near electrical installations, pipelines, or environments with stray currents.

(3) Resistance to Moisture and Freeze-Thaw Cycles

Unlike concrete, PVC does not absorb water and therefore does not crack or spall during freeze-thaw cycles. This resistance to moisture penetration makes PVC sheet piles ideal for climates with large temperature variations.

5. Comparative Performance vs. Traditional Materials

| Property | PVC Sheet Piles | Steel Sheet Piles | Concrete Piles | Timber Piles |

| Strength | Moderate | Very High | High | Moderate |

| Weight | Very Light | Heavy | Heavy | Light |

| Corrosion Resistance | Excellent | Poor (unless coated) | Moderate | Poor |

| Maintenance | Minimal | High | Moderate | High |

| Lifespan | 50+ years | 20–40 years | 30–50 years | 10–20 years |

| Cost | Low to Medium | High | Medium | Low |

| Installation | Easy | Requires heavy equipment | Requires heavy equipment | Easy |

As seen from the comparison, PVC sheet piles may not match steel in raw strength but clearly outperform it in corrosion resistance, maintenance requirements, and cost efficiency, especially in moderate-load, corrosive, or wet environments.

6. Environmental and Economic Benefits

Beyond mechanical performance, PVC sheet piles also contribute to sustainable construction practices. They are fully recyclable, require less energy to manufacture, and generate lower carbon emissions compared to steel and concrete alternatives.

Moreover, their lightweight nature reduces transportation and installation energy, further minimizing environmental impact. Combined with their long lifespan and zero maintenance requirements, PVC sheet piles offer a highly cost-effective and eco-friendly solution for infrastructure development.

7. Limitations and Considerations

While PVC sheet piles offer many advantages, they do have some limitations:

- Lower load capacity: Not suitable for extremely high structural loads or deep foundation applications.

- Thermal sensitivity: Mechanical properties can vary with temperature; performance may decline in extremely hot or cold conditions.

- Design limitations: Must be properly engineered to prevent excessive deflection in tall retaining structures.

In many cases, engineers overcome these limitations by using PVC sheet piles in combination with anchoring systems or hybrid solutions that include steel reinforcement where necessary.

Conclusion

PVC sheet piles provide an innovative, sustainable, and durable alternative to traditional piling materials. Their combination of adequate structural strength, exceptional durability, and unmatched corrosion resistance makes them ideal for marine, environmental, and infrastructure applications.

While they may not replace steel in heavy-load structures, PVC sheet piles offer unparalleled performance in projects that prioritize longevity, cost efficiency, and environmental resilience. With continued improvements in polymer technology and structural design, PVC sheet piles are poised to play an even greater role in the future of sustainable construction and coastal protection.

English

English 中文简体

中文简体