Feb 28,2026

Introduction to PVC Sheet Piling in Coastal Environments

PVC sheet piling has become an increasingly popular alternative to traditional materials such as steel, timber, and concrete in marine and coastal engineering. Designed for seawalls, bulkheads, retaining walls, and shoreline protection, PVC sheet piles combine corrosion resistance, low maintenance, and cost efficiency. In coastal and marine environments where saltwater exposure and wave action accelerate material degradation, PVC sheet piling offers a sustainable and practical solution.

Material Properties and Corrosion Resistance

One of the primary reasons PVC sheet piling excels in marine applications is its inherent resistance to corrosion. Unlike steel, which rusts, or timber, which rots and attracts marine borers, PVC does not react with saltwater or other environmental chemicals. This makes it an excellent choice for long-term installations in areas with high salinity and constant moisture exposure.

Additionally, modern formulations of unplasticized polyvinyl chloride (uPVC) include UV stabilizers that protect against sunlight degradation. This ensures that PVC sheet piles maintain their strength, color, and flexibility over decades, even under constant UV exposure in coastal regions.

Mechanical Strength and Structural Performance

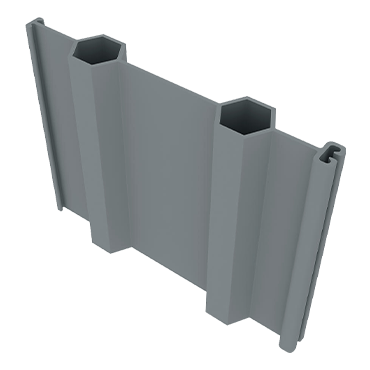

While PVC is not as strong as steel, it provides sufficient rigidity and tensile strength for light to medium-duty marine applications. When properly designed and installed, PVC sheet piling can withstand hydrostatic pressure, soil loads, and tidal fluctuations effectively. Manufacturers often reinforce PVC profiles with interlocking designs that distribute loads evenly across panels.

The structural performance can be further enhanced through anchoring systems, tie rods, and concrete caps that stabilize the wall. In most shoreline protection projects, PVC sheet piling performs efficiently up to moderate water depths where wave impact and pressure remain within design limits.

Comparison of PVC Sheet Piling with Other Materials

| Material Type | Corrosion Resistance | Maintenance | Lifespan | Cost |

| PVC Sheet Piling | Excellent | Low | 50+ years | Moderate |

| Steel Sheet Piling | Poor (without coating) | High | 25–40 years | High |

| Timber Sheet Piling | Moderate | Moderate to High | 15–25 years | Low |

Ease of Installation in Marine Conditions

PVC sheet piling is lightweight and easier to handle than steel or concrete, reducing transportation and installation costs. This characteristic is particularly beneficial in remote coastal areas where heavy machinery access is limited. Installation methods typically include vibration, pressing, or driving depending on soil conditions and wall depth.

Because of its lighter weight, PVC sheet piling can be installed with smaller, less expensive equipment, leading to faster project completion and reduced labor costs. The interlocking joint design ensures watertight connections and stability even under tidal movements.

Environmental and Sustainability Benefits

PVC sheet piling offers significant environmental benefits compared to traditional materials. Its production involves less energy consumption than steel manufacturing, and many suppliers now use recyclable PVC compounds. Moreover, because the material is inert and non-toxic, it does not leach harmful chemicals into the surrounding water, making it safe for aquatic ecosystems.

The extended lifespan of PVC sheet piling also reduces the frequency of replacement and disposal, lowering the overall environmental footprint. In coastal restoration and flood control projects, this durability contributes to long-term sustainability.

Maintenance and Longevity in Coastal Applications

PVC sheet piling requires minimal maintenance once installed. Unlike steel, which requires repainting or re-coating, or timber, which needs periodic treatment, PVC only needs occasional inspections to check for physical damage or displacement. The surface is smooth and resistant to marine growth, preventing the accumulation of algae or barnacles that typically increase drag and stress on other materials.

Field data and laboratory testing indicate that properly installed PVC sheet piling can last over 50 years, even in harsh marine environments. Its resistance to ultraviolet light, impact, and chemical exposure ensures consistent performance throughout its service life.

Common Applications in Coastal and Marine Projects

PVC sheet piling is used in a wide range of coastal and marine engineering projects due to its adaptability and long-term resilience. Common applications include:

- Shoreline and riverbank stabilization to prevent erosion

- Seawalls and bulkheads for marina and harbor protection

- Flood control barriers and levees

- Retaining walls in wetland restoration projects

- Wave barriers and dock edge reinforcement

Conclusion: Why PVC Sheet Piling Excels in Marine Use

PVC sheet piling has proven itself as a durable, cost-effective, and environmentally friendly solution for marine and coastal engineering. Its corrosion resistance, easy installation, and low maintenance make it ideal for long-term shoreline protection and waterfront development. When designed correctly and installed under appropriate conditions, PVC sheet piling not only performs reliably under tidal and wave action but also contributes to sustainable coastal management for decades.

English

English 中文简体

中文简体