Nov 24,2025

Vinyl sheet piles have become an increasingly popular solution in civil engineering, marine construction, and flood protection projects. Made from high-density PVC or other durable vinyl compounds, these sheet piles offer an alternative to traditional steel, concrete, or timber piles, combining durability, low maintenance, and environmental benefits. One of the key questions engineers and developers often face is how vinyl sheet piles perform across different soil and water conditions, which can vary widely in urban, coastal, and inland projects.

This article explores the performance characteristics of vinyl sheet piles in a range of geotechnical and hydrological environments, highlighting their strengths, limitations, and practical applications.

Understanding Vinyl Sheet Piles

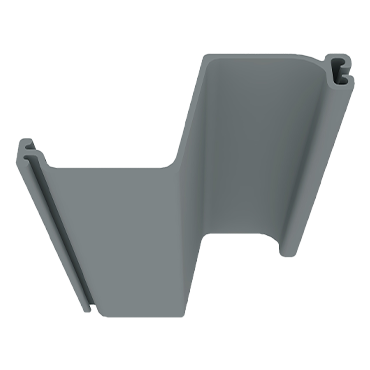

Vinyl sheet piles are interlocking panels used to form retaining walls, bulkheads, cofferdams, and flood barriers. The vinyl material provides several advantages:

- Corrosion resistance: Unlike steel, vinyl does not rust or degrade in water or chemically aggressive soils.

- Lightweight construction: Easier to transport, handle, and install than heavier steel or concrete alternatives.

- Flexibility: Vinyl panels can absorb minor soil movement without cracking.

- Low maintenance: Resistant to biofouling, rot, and UV degradation with proper formulation.

- Recyclability: Many vinyl sheet piles are made from recyclable materials, enhancing sustainability.

These characteristics make vinyl sheet piles particularly suitable for challenging environments where moisture, salinity, or chemical exposure can compromise traditional materials.

Performance in Different Soil Conditions

The soil environment plays a critical role in the effectiveness of vinyl sheet piles. The following factors are important:

1. Sandy Soils

Sandy soils are loose, granular, and often prone to erosion.

Performance:

- Vinyl sheet piles can penetrate sandy soil efficiently due to their lightweight nature and ease of driving.

- Interlocking panels help resist lateral movement and erosion.

- Drainage behind the piles is essential to reduce hydrostatic pressure and prevent soil washout.

Advantages:

- Flexible vinyl can accommodate slight settlement without structural failure.

- Corrosion resistance ensures longevity in moist or saline sand near coastal areas.

Considerations:

- Adequate depth of embedment is necessary to ensure stability, especially in loose or shifting sand.

- Anchoring systems or tiebacks may be needed for high lateral loads.

2. Clay Soils

Clay soils are cohesive, heavy, and can expand or shrink depending on moisture content.

Performance:

- Vinyl sheet piles perform well in clay due to their ability to interlock tightly and resist lateral soil pressures.

- The flexibility of vinyl allows the wall to adjust to slight soil swelling and shrinkage without cracking.

Advantages:

- Resistant to corrosion from sulfates and other chemicals present in clay-rich soils.

- Lightweight panels make installation easier even in dense or wet clay.

Considerations:

- Excessive swelling or shrinkage can create pressure variations, requiring careful design of embedment depth and wall thickness.

- Drainage systems behind the wall may still be necessary to relieve hydrostatic pressure.

3. Rocky or Gravelly Soils

Gravel and rocky soils can create obstacles during pile driving.

Performance:

- Vinyl sheet piles are more flexible than steel, which allows minor deflection around obstructions, but large rocks may still impede installation.

- Pre-drilling or specialized vibratory driving techniques may be required in extremely coarse soils.

Advantages:

- Lightweight vinyl reduces stress on driving equipment, making it easier to maneuver around dense areas.

Considerations:

- Damage to panels during installation must be monitored.

- Interlocks must remain intact to maintain structural integrity under lateral load.

4. Soft or Peaty Soils

Soft soils, including peat or highly organic soils, are compressible and low in bearing capacity.

Performance:

- Vinyl sheet piles can be installed with minimal disturbance, helping preserve soil structure.

- Flexibility of vinyl allows accommodation of uneven settlement.

Advantages:

- Corrosion-resistant properties prevent degradation in moisture-rich environments.

- Lightweight piles reduce the risk of excessive settlement or soil compression.

Considerations:

- Support systems, such as tiebacks or bracing, may be necessary to prevent lateral deflection.

- Additional embedment depth is often required to achieve stability.

Performance in Different Water Conditions

Vinyl sheet piles are also evaluated based on their performance in various water environments, including fresh water, brackish water, and marine conditions.

1. Freshwater Environments

Freshwater rivers, lakes, and reservoirs provide moderate chemical exposure and limited salt corrosion.

Performance:

- Vinyl sheet piles perform exceptionally well in freshwater, maintaining strength, flexibility, and interlock integrity over decades.

- Low maintenance reduces lifecycle costs compared to steel, which requires regular coating or galvanization.

Advantages:

- Resistant to algae and biofouling when properly treated.

- Easy to clean and inspect during routine maintenance.

Considerations:

- Hydrostatic pressure must be considered, especially for deep water applications.

- Proper anchoring ensures stability during high water flow events.

2. Brackish Water and Estuarine Conditions

Estuaries and tidal rivers combine freshwater and seawater, exposing materials to moderate salinity and varying chemical conditions.

Performance:

- Vinyl’s corrosion resistance ensures long-term performance in brackish water where steel may rapidly degrade.

- Flexibility accommodates minor water level fluctuations without damage.

Advantages:

- Lower maintenance cost compared to metal solutions.

- Resistant to biofouling, marine growth, and sediment abrasion.

Considerations:

- UV exposure above the waterline must be considered; panels with UV inhibitors perform best.

- Anchoring and bracing systems must be adapted to tidal or fluctuating water levels.

3. Marine and High-Salinity Environments

Coastal zones, harbors, and seawalls expose materials to extreme salinity, wave action, and occasional debris impact.

Performance:

- Vinyl sheet piles are highly effective in resisting chemical and salt-induced corrosion, unlike steel or untreated metals.

- Their flexibility and resilience reduce the risk of cracking or structural failure from wave impact.

Advantages:

- Long-term durability in saltwater environments.

- Lightweight panels simplify installation in offshore or tidal conditions.

- Non-toxic and environmentally safe for aquatic life.

Considerations:

- Proper interlock sealing is critical to prevent water seepage behind the wall.

- Floating debris and large waves may require supplemental bracing or heavier anchoring.

Installation Techniques Affecting Performance

The performance of vinyl sheet piles also depends on installation methods:

- Vibratory Driving: Common for soft to medium soils; lightweight vinyl minimizes damage.

- Hammer or Hydraulic Driving: Useful in denser soils or when precise depth is required.

- Pre-Drilling: Necessary for rocky or gravelly soils to prevent panel damage.

- Interlock Maintenance: Ensuring tight interlocks is essential for structural integrity and water resistance.

Correct installation ensures vinyl sheet piles perform optimally across diverse soil and water conditions.

Advantages of Vinyl Sheet Piles

- Corrosion and Chemical Resistance: Ideal for both inland and coastal projects.

- Lightweight and Flexible: Easier installation, especially in restricted sites.

- Low Maintenance: Reduces long-term operational costs.

- Environmentally Friendly: Non-toxic, recyclable material.

- Durable: Long service life in most soil and water conditions, including high salinity environments.

Limitations and Considerations

- Lower Structural Strength: Vinyl may require supplemental support in high-load applications.

- UV Exposure: Prolonged sunlight can degrade some vinyl unless UV-stabilized.

- High Impact Vulnerability: Extreme impacts from debris or heavy machinery can damage panels.

Despite these limitations, proper design, installation, and maintenance ensure effective performance in most applications.

Conclusion

Vinyl sheet piles are a versatile and durable solution for retaining walls, bulkheads, and flood protection systems in diverse soil and water conditions. Their performance is characterized by:

- Excellent corrosion resistance in freshwater, brackish, and marine environments.

- Flexibility and adaptability in sandy, clayey, peaty, and rocky soils.

- Low maintenance and long-term durability, reducing lifecycle costs compared to steel or concrete alternatives.

- Ease of installation and customization, accommodating irregular pool, dock, or shoreline geometries.

While design considerations such as soil type, water salinity, wave action, and load requirements must be carefully evaluated, vinyl sheet piles provide a safe, efficient, and environmentally friendly option for modern construction projects. Their combination of flexibility, chemical resistance, and structural integrity makes them a reliable choice for engineers and developers facing a range of geotechnical and hydrological challenges.

English

English 中文简体

中文简体