Feb 28,2026

Vinyl sheet piles have emerged as a popular alternative to traditional steel and concrete sheet piles in various construction and civil engineering applications. Known for their durability, corrosion resistance, and ease of installation, vinyl sheet piles are particularly well-suited for projects in environments where water exposure, soil variability, and long-term maintenance are concerns. Understanding how vinyl sheet piles perform in different soil and water conditions is critical for engineers, architects, and construction professionals to ensure structural stability and project longevity. This article explores the performance characteristics of vinyl sheet piles across a range of environmental conditions.

1. Overview of Vinyl Sheet Piles

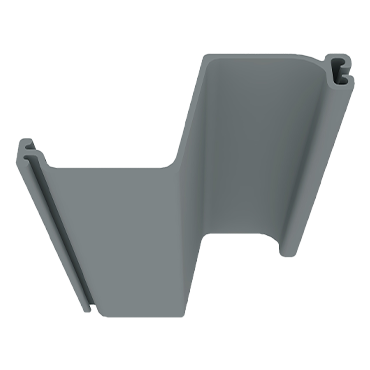

Vinyl sheet piles are made from high-density polyvinyl chloride (HDPE or PVC), often reinforced with additives to enhance structural strength and UV resistance. These piles are designed to interlock, forming a continuous wall capable of retaining soil, resisting water intrusion, and supporting construction loads. Key advantages of vinyl sheet piles include:

- Corrosion resistance: Unlike steel, vinyl does not rust, making it ideal for marine and high-moisture environments.

- Lightweight construction: Easier handling and faster installation compared to steel or concrete piles.

- Flexibility: Suitable for projects requiring slight flexibility to adapt to soil settlement or movement.

- Low maintenance: Resistant to chemical attack and biological growth.

While vinyl sheet piles are widely used for seawalls, bulkheads, cofferdams, and flood control structures, their performance depends significantly on soil type, water conditions, and installation techniques.

2. Performance in Sandy Soil

Sandy soils are loose, granular, and often found near coastal or riverbank areas. They are highly permeable, allowing water to pass through easily, which can affect retaining structures. Vinyl sheet piles perform well in sandy soils due to several factors:

- Interlock stability: The interlocking design provides a continuous wall that resists lateral pressure from loose soil.

- Flexibility: Vinyl’s slight flexibility allows the wall to adapt to minor soil movement without cracking or failure.

- Anchoring: Sand allows for effective use of tiebacks, wales, or deadman anchors to enhance lateral stability.

However, designers must consider the depth of embedment and lateral earth pressure carefully, as sandy soils exert significant horizontal force, especially when saturated with water. Adequate anchoring and proper wall design are crucial to prevent wall deflection or overturning.

3. Performance in Clay Soils

Clay soils are cohesive and typically less permeable than sandy soils, which can influence both the lateral pressure on sheet piles and water flow patterns. Vinyl sheet piles are well-suited to clay environments due to the following characteristics:

- Reduced water seepage: The impermeable nature of vinyl, combined with tight interlocks, prevents water from passing through the wall, even in low-permeability soils.

- Pressure resistance: Clay soils exert less lateral pressure when dry, but can swell or shrink depending on moisture content. Vinyl’s flexibility accommodates minor volume changes without compromising structural integrity.

- Ease of installation: Vinyl piles can be driven or vibrated into clay without excessive equipment force due to their lightweight construction.

Engineers must still account for potential soil consolidation over time, particularly in soft clay, which can lead to wall settlement. Designing for proper embedment depth and, if necessary, supplemental anchoring ensures long-term stability.

4. Performance in Silt and Mixed Soils

Silt and mixed soils present a combination of granular and cohesive properties, making their behavior less predictable than pure sand or clay. Vinyl sheet piles perform effectively in these conditions when proper design considerations are followed:

- Seepage control: Vinyl’s impermeable profile prevents water from seeping through silt layers, which may otherwise cause erosion or piping.

- Settlement adaptability: The flexible nature of vinyl allows the wall to accommodate minor soil settlement without cracking.

- Anchor efficiency: Mixed soils can support anchors or tieback systems effectively, provided geotechnical evaluation is performed.

Designers must consider soil stratification, as layers with varying permeability can create differential pressures and localized stress points. Proper embedment and structural support are essential for long-term performance.

5. Performance in Wet and Saturated Soils

Many vinyl sheet pile projects involve high groundwater tables or submerged conditions, such as bulkheads, marinas, or flood control walls. Vinyl sheet piles excel in wet and saturated soils due to several advantages:

- Corrosion-free: Unlike steel piles, vinyl is immune to rust and chemical degradation caused by constant water exposure.

- No chemical leaching: Vinyl does not react with water or common soil chemicals, ensuring environmental safety.

- Hydraulic sealing: Interlocking profiles prevent water leakage, reducing soil erosion behind the wall.

When installed in submerged conditions, it is crucial to verify the structural design against hydrostatic pressure. Vinyl sheet piles may require additional bracing, wales, or tiebacks to resist water-driven lateral forces, particularly during flooding or tidal changes.

6. Performance in Saline and Coastal Environments

Coastal and marine projects present unique challenges due to high salinity, tidal forces, and potential wave impact. Vinyl sheet piles are particularly effective in these environments:

- Saltwater resistance: Vinyl is impervious to corrosion caused by saltwater, unlike steel or untreated metals.

- UV resistance: Many vinyl sheet piles include UV stabilizers to prevent degradation under constant sunlight.

- Wave impact absorption: The slight flexibility of vinyl allows it to withstand minor wave-induced stress without cracking.

In areas with strong currents or heavy wave action, engineers may reinforce vinyl walls with timber or steel wales, anchors, or protective fendering systems to enhance durability.

7. Thermal and Freeze-Thaw Performance

Vinyl sheet piles are affected by temperature fluctuations, which can cause expansion or contraction. In regions with extreme temperatures or freeze-thaw cycles:

- Flexibility reduces cracking: Vinyl can expand or contract slightly without breaking, unlike brittle concrete.

- Temperature limits: Proper specification ensures vinyl maintains structural integrity at both high and low temperatures.

- Ice impact: In cold climates, the material can absorb minor ice forces without damage, though extreme ice loads may require supplemental reinforcement.

Design considerations include allowances for thermal movement and potential ice loads to prevent long-term deformation.

8. Installation Considerations

The performance of vinyl sheet piles in different soils and water conditions is closely linked to installation techniques:

- Driving methods: Vibratory hammers, hydraulic presses, or impact hammers are commonly used depending on soil type. Sandy or loose soils often require vibratory driving, while clay or mixed soils may benefit from hydraulic pressing.

- Pre-drilling: In very dense soils, pre-drilling may be necessary to facilitate pile insertion.

- Interlocking precision: Ensuring tight interlocks between sheets is critical to prevent seepage and maintain structural stability.

- Anchoring: Tiebacks or wales are often required in deep walls or high-pressure environments.

Proper installation guarantees that vinyl sheet piles perform as designed across varying environmental conditions.

9. Advantages Over Traditional Materials

Compared to steel and concrete, vinyl sheet piles offer several performance advantages in diverse soil and water conditions:

- Corrosion and chemical resistance in marine and chemically active soils.

- Lower weight reduces installation costs and equipment requirements.

- Flexibility accommodates soil movement, settlement, and freeze-thaw cycles.

- Low maintenance eliminates the need for protective coatings or ongoing rust prevention.

- Environmental safety due to inert material composition.

These benefits make vinyl sheet piles an attractive option for coastal, riverbank, and flood control projects.

10. Limitations and Design Considerations

Despite their advantages, vinyl sheet piles have limitations:

- Load capacity: Vinyl has lower ultimate strength than steel, requiring design adjustments for high-load or deep wall applications.

- Impact sensitivity: Heavy mechanical impacts or extreme wave forces may damage the piles without supplemental reinforcement.

- UV exposure: Long-term sunlight exposure without stabilizers may degrade material properties.

Engineers must carefully evaluate site conditions and choose the appropriate vinyl grade, pile thickness, and reinforcement methods.

Conclusion

Vinyl sheet piles provide a durable, flexible, and cost-effective solution for retaining walls, seawalls, bulkheads, and other civil engineering projects. Their performance across different soil and water conditions—sandy, clay, silt, saturated, saline, and freeze-thaw environments—is largely influenced by their interlocking design, flexibility, corrosion resistance, and proper installation techniques.

By understanding soil characteristics, water levels, and environmental challenges, engineers can design and install vinyl sheet pile systems that maintain structural integrity, resist seepage, and require minimal maintenance. While vinyl piles may not match steel in ultimate load capacity, their long-term durability, ease of installation, and environmental benefits make them a highly effective choice for modern construction projects in diverse conditions.

English

English 中文简体

中文简体