Oct 31,2025

Seawalls are vital coastal infrastructure, designed to protect shorelines, prevent erosion, and safeguard properties from the impact of tides and storms. Traditionally, wood and concrete have been the materials of choice for constructing seawalls. However, vinyl seawall panels have emerged as a modern alternative, offering durability, low maintenance, and environmental advantages. Understanding how vinyl seawall panels perform compared to traditional wood and concrete seawalls is essential for property owners, engineers, and municipal planners considering coastal protection solutions.

Understanding Vinyl Seawall Panels

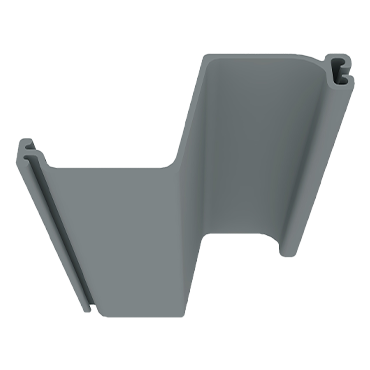

Vinyl seawall panels are made from high-density PVC (polyvinyl chloride) or similar synthetic materials. They are designed to resist the harsh conditions of marine environments, including saltwater corrosion, UV radiation, and fluctuating temperatures. These panels can be installed vertically or horizontally, often interlocking to create a continuous barrier along the shoreline.

Key features of vinyl seawall panels include:

- Corrosion resistance: Unlike metal components, vinyl does not rust or degrade in saltwater.

- Low maintenance: Requires minimal cleaning and rarely needs painting or sealing.

- Flexibility: Can absorb minor impacts and adjust to small ground movements without cracking.

- Aesthetic appeal: Available in various colors and textures, vinyl panels often mimic natural wood or stone finishes.

Comparing Performance: Vinyl vs. Wood Seawalls

1. Durability and Longevity

Wood Seawalls: Traditionally made from pressure-treated timber or hardwood, wood seawalls are susceptible to decay, rot, and marine borers such as shipworms. Even with treatments, wood typically lasts 10 to 20 years under harsh marine conditions.

Vinyl Seawall Panels: Vinyl is naturally resistant to rot, insect damage, and marine organisms. With proper installation, vinyl seawall panels can last 30 to 50 years, making them a long-term solution for coastal protection.

Key takeaway: Vinyl panels significantly outperform wood in terms of durability and service life, especially in saltwater environments.

2. Maintenance Requirements

Wood Seawalls: Wooden seawalls require frequent inspections, sealing, and occasional replacement of damaged planks. Neglecting maintenance accelerates deterioration and reduces structural integrity.

Vinyl Seawall Panels: Maintenance is minimal—primarily periodic cleaning to remove debris, algae, or dirt. No painting, staining, or chemical treatments are needed.

Key takeaway: Vinyl panels offer a low-maintenance alternative, reducing long-term labor and cost.

3. Resistance to Environmental Factors

Wood Seawalls: Wood can swell, warp, or crack due to moisture absorption and temperature fluctuations. Storm surges or heavy impacts can cause significant structural damage.

Vinyl Seawall Panels: Vinyl is dimensionally stable and resists warping, cracking, or splitting. It can flex slightly under pressure, helping it withstand wave impacts better than rigid wood.

Key takeaway: Vinyl panels provide superior resistance to environmental stresses compared to wood.

4. Aesthetics and Customization

Wood Seawalls: Natural wood provides an authentic appearance, which many property owners prefer for its aesthetic warmth. However, color fading and surface weathering are common issues.

Vinyl Seawall Panels: Modern vinyl panels can replicate wood grain or stone textures while retaining consistent color and appearance over time. Some panels even offer UV protection to prevent fading.

Key takeaway: Vinyl combines durability with customizable aesthetics, offering a long-lasting attractive alternative to wood.

Comparing Performance: Vinyl vs. Concrete Seawalls

1. Structural Strength

Concrete Seawalls: Concrete is highly durable and strong, capable of withstanding heavy wave loads and significant impacts. Properly reinforced concrete seawalls can last 50 years or more.

Vinyl Seawall Panels: While vinyl is not as rigid as concrete, modern engineering allows vinyl panels to handle moderate wave pressures and typical coastal forces. For high-energy shorelines, vinyl seawalls may require additional support, such as steel reinforcements or piling.

Key takeaway: Concrete has superior compressive strength, but vinyl panels can perform adequately for most residential and low-to-moderate energy coastal applications.

2. Installation and Flexibility

Concrete Seawalls: Installing concrete seawalls is labor-intensive, requiring heavy equipment, curing time, and precise engineering. Once set, concrete structures are rigid and difficult to modify.

Vinyl Seawall Panels: Vinyl panels are lightweight, easy to handle, and can be installed with minimal heavy equipment. They are modular, allowing for easier repairs, adjustments, or extensions.

Key takeaway: Vinyl offers faster, less labor-intensive installation and greater flexibility for modifications.

3. Maintenance Requirements

Concrete Seawalls: Concrete may develop cracks, spalling, or surface degradation over time, particularly in freeze-thaw environments or when exposed to saltwater. Repairs can be costly and require professional expertise.

Vinyl Seawall Panels: Vinyl does not crack, chip, or spall. Maintenance is primarily cleaning, making it far less costly over time.

Key takeaway: Vinyl requires significantly less maintenance than concrete, reducing lifecycle costs.

4. Environmental Considerations

Concrete Seawalls: Concrete production is energy-intensive and has a higher carbon footprint. Additionally, poorly designed concrete structures can accelerate shoreline erosion in adjacent areas.

Vinyl Seawall Panels: Vinyl is recyclable, lightweight, and less disruptive during installation. While it is a plastic product, its long lifespan and minimal maintenance reduce the overall environmental impact compared to frequent wood replacements or concrete repairs.

Key takeaway: Vinyl panels can be an environmentally friendlier choice when considering installation and lifecycle impacts.

Practical Considerations for Choosing Vinyl Seawall Panels

When deciding whether vinyl seawall panels are suitable, consider the following factors:

- Wave Energy: For high-energy coastlines, additional reinforcement may be needed.

- Budget: Vinyl offers lower long-term maintenance costs, even if initial costs are comparable to wood or concrete.

- Aesthetic Preferences: Vinyl can replicate natural finishes while providing consistent performance.

- Environmental Impact: Consider sustainability, recyclability, and ease of installation.

- Lifespan Requirements: Vinyl panels generally offer a lifespan similar to concrete and far exceeding wood.

Conclusion

Vinyl seawall panels are a modern alternative to traditional wood and concrete seawalls, offering a unique combination of durability, low maintenance, flexibility, and aesthetic versatility.

- Compared to wood, vinyl panels outperform in almost every aspect: they resist rot, marine borers, warping, and require minimal maintenance, with a longer lifespan.

- Compared to concrete, vinyl provides easier installation, lower maintenance costs, and environmental benefits, while performing adequately under moderate wave energy conditions. Concrete remains superior in terms of raw structural strength for extreme coastal environments.

Ultimately, vinyl seawall panels provide an efficient, long-lasting, and visually appealing solution for protecting shorelines, particularly for residential or moderate-energy coastal areas. They represent a balance between performance, cost-effectiveness, and sustainability, making them an increasingly popular choice for modern waterfront projects.

English

English 中文简体

中文简体